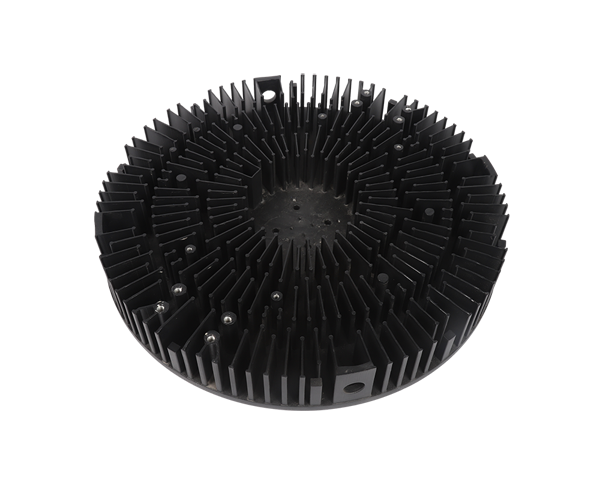

Pure aluminum die casting has emerged as a crucial manufacturing technique for environmental protection equipment, offering a combination of lightweight, high - strength, and corrosion - resistant properties that are highly suitable for the deman...

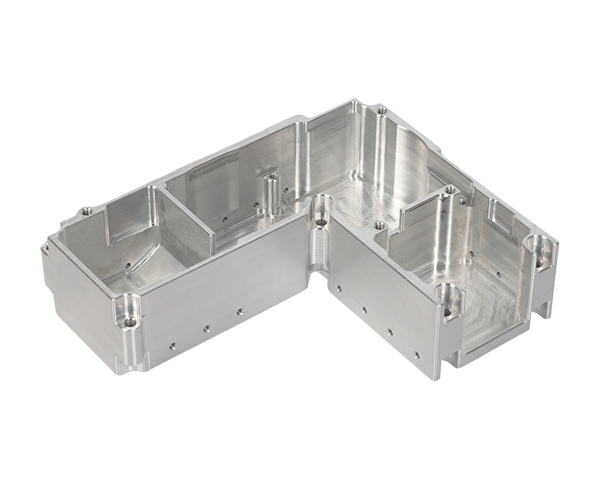

Aluminum die casting with metal molds is a widely - used manufacturing process that offers high - volume production capabilities with excellent dimensional accuracy and surface finish. This process involves injecting molten aluminum under high pr...

Zinc alloy die casting is a versatile manufacturing process widely used in various industries due to its cost - effectiveness, dimensional accuracy, and ability to produce complex geometries. Zinc alloys can be classified based on their chemical ...

The alloy die-casting process for aeroengine blades is a highly sophisticated and precision-oriented manufacturing technique that plays a crucial role in the aerospace industry. Aeroengine blades operate under extreme conditions, including high t...

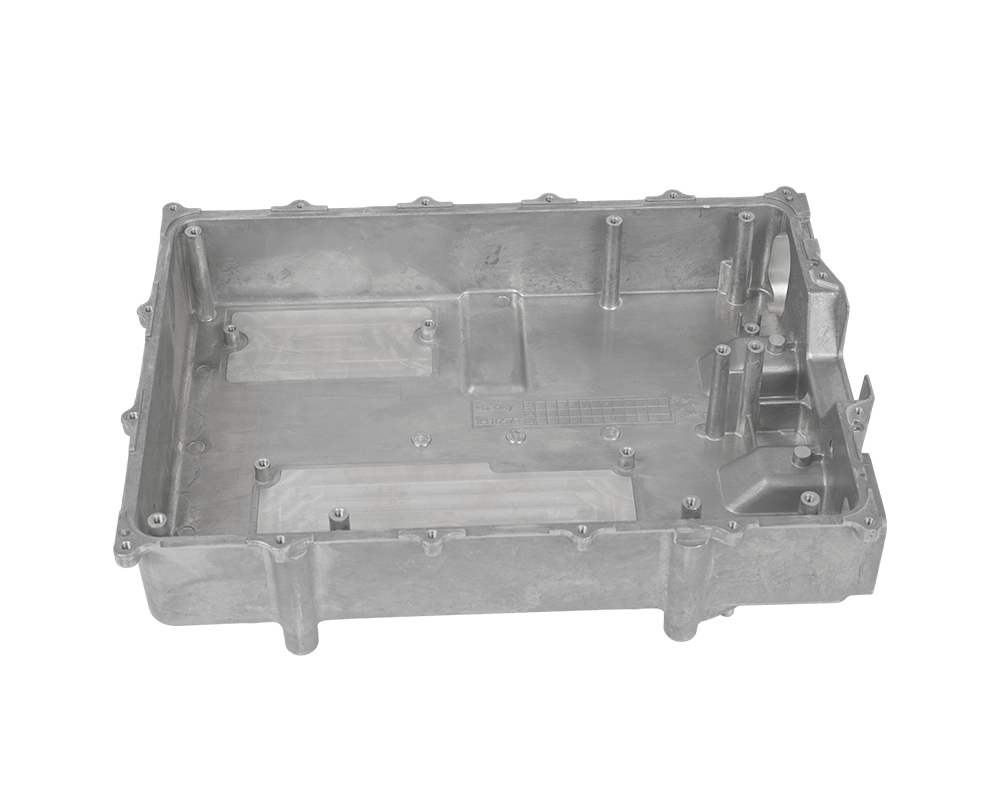

The waterproof performance of aluminum die - castings is of utmost importance, especially for components used in outdoor or humid environments. To achieve excellent waterproofing, several factors need to be considered during the design and manufa...

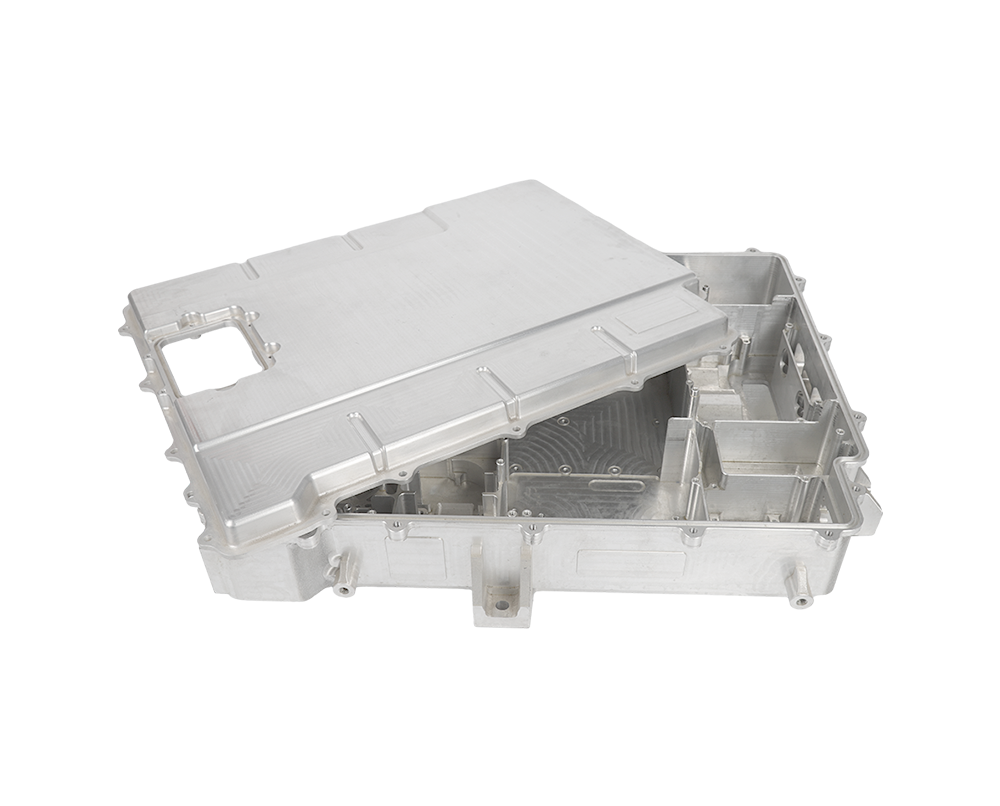

Aluminum die - castings have become an integral part of the fingerprint recognition technology in smart door locks, playing a crucial role in enhancing the functionality, durability, and user experience of these advanced security devices. In the...