Analysis of Water Defects in Zinc Alloy Die Casting ProductsWater defects, also known as flow lines or striations, are visible irregularities on the surface of zinc alloy die castings, appearing as wavy or banded patterns. These defects arise from ...

Optimizing die casting processes to increase productivity involves a combination of technological advancements, process refinements, and data-driven adjustments, all aimed at reducing cycle times, minimizing defects, and maximizing machine utilizatio...

Carbon fiber tubes and glass fiber tubes are both popular composite materials, but their strength characteristics differ significantly, making them suitable for distinct applications. Carbon fiber tubes exhibit exceptional tensile strength, typically...

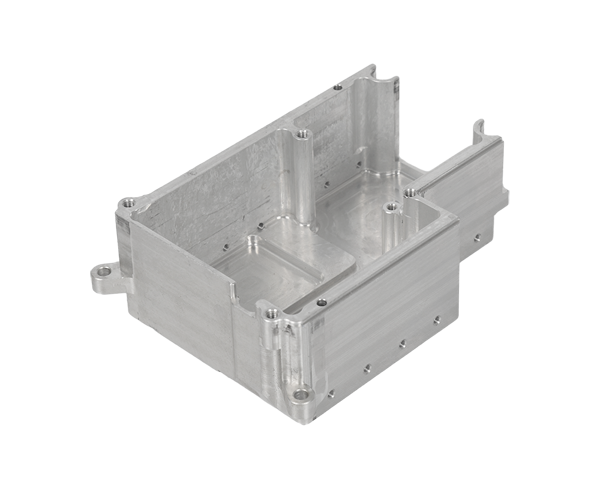

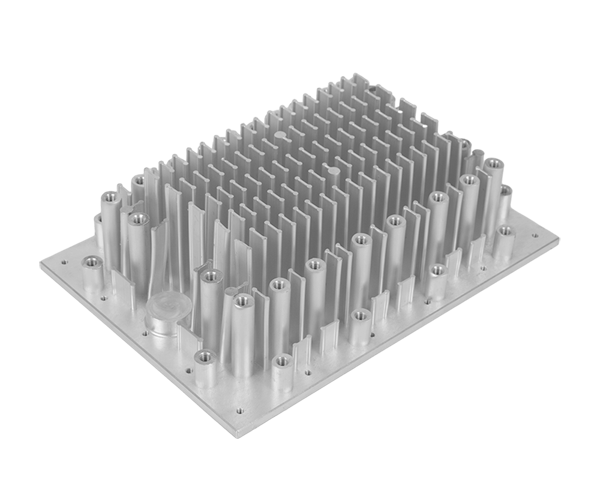

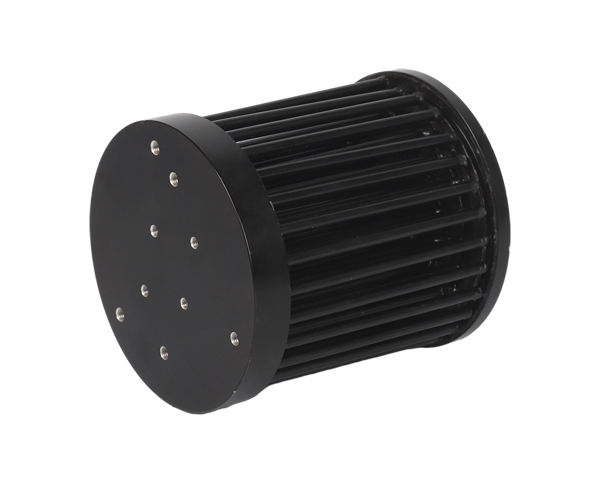

Aluminum die casting has become a cornerstone of modern manufacturing, offering a unique combination of properties that make it ideal for diverse industries. Its advantages stem from the material’s inherent characteristics and the efficiency of the d...

Aluminum alloy die casting, while efficient in producing complex components, poses several environmental challenges, primarily related to energy consumption, emissions, and waste generation. However, proactive measures can mitigate these impacts, ali...

Pure aluminum die-casting has emerged as a critical manufacturing technology for instruments and meters, driven by the demand for lightweight, corrosion-resistant, and dimensionally precise components. In this field, the purity of aluminum (typica...