2024-02-26 hits:0 source:News

The polishing and deburring equipment for die-casting parts can polish workpieces in batches. After polishing, tools can be used to separate them in batches, greatly improving work efficiency and effectiveness.

The polishing and deburring treatment equipment for die-casting parts is designed for dead corners such as small hardware and accessories, with excellent internal hole treatment effect. It can achieve the removal of dust, burrs, and improve the surface brightness of the product, which is a characteristic that other types of polishing equipment cannot compare with.

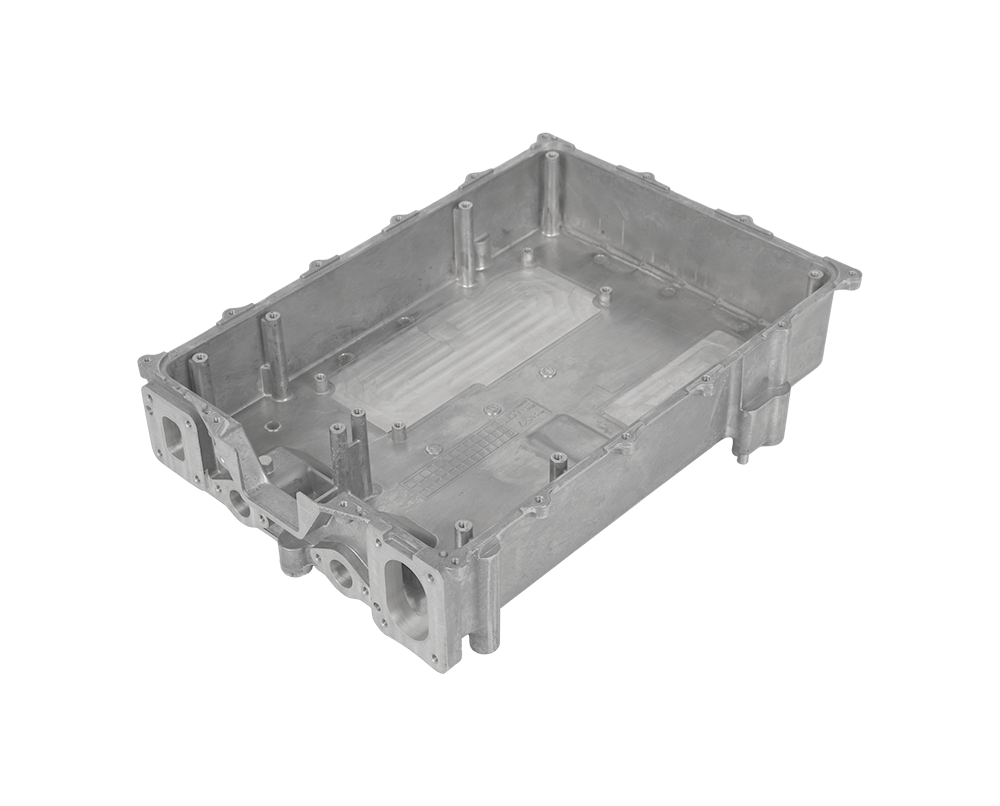

At present, for the problem of burrs in aluminum alloy die-casting parts, efficient treatment methods are commonly used. Die casting polishing and deburring equipment is widely used, and the advantages of using this equipment are obvious. It can effectively deburr and polish the inner holes, concave convex surfaces, dead corners, and internal and external threads of castings. Using automatic deburring equipment and manual deburring methods, a simple and efficient processing method is used to achieve a product without burrs, making customer assembly smoother.

Read recommendations:

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible