Aluminum alloy die castings may experience air oxidation and looseness during the die casting pr

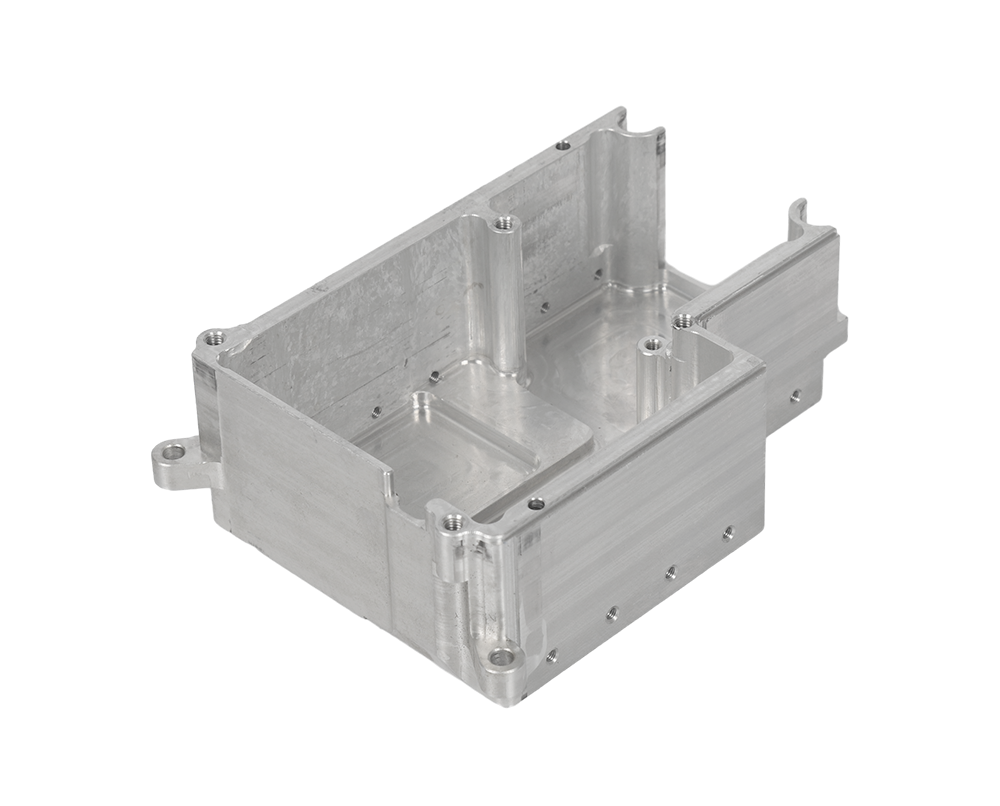

Due to the excellent casting performance, mechanical properties, toughness, and thermal conducti

In the production process of aluminum alloy die-casting parts, various defect problems often occ

Those who believe in the decompression casting industry know that before the production of zinc

Many friends may be unfamiliar with zinc alloy die-casting, but in fact, its application range i

Aluminum alloy die castings must undergo heat treatment during factory processing, and there are