2024-03-07 hits:0 source:News

1. Good product quality

There are high dimensional accuracy in the parts, up to CT4 ~ CT8 grade, surface roughness Ra value is 0.8 ~ 6.3μm, the lowest Ra value is 0.2μm, die casting surface layer grain is relatively fine, dense organization, surface layer hardness and strength are relatively high, the strength is generally 25% ~ 30% higher than sand casting, but the extended aluminum is reduced by about 70%, and the size is stable. Good interchangeability, can be die-cast thin-walled complex castings, for example, the current zinc alloy die-casting minimum wall thickness up to 0.3mm, aluminum alloy castings up to 0.5mm, the minimum casting aperture is 0.7mm, the minimum pitch is 0.75mm.

2. High production efficiency

General horizontal cold chamber die casting machine average 8h can die casting 600-700 times, small hot chamber die casting machine average 8h can die casting 3000-7000 times, die casting die life factory, a die casting die, die casting aluminum alloy, life can reach hundreds of thousands of words, or even millions of times, suitable for mass production, and can achieve a mold multi-cavity process, Its output doubled with the increase of more goods, easy to achieve mechanization and automation.

3. Good economic effect

Due to the advantages of precise size and smooth surface of die casting parts, generally no longer mechanical processing can be used directly, or the processing amount is small, so it not only improves the metal utilization rate, but also reduces a large number of processing equipment and working hours, casting prices are cheap, can use combination die casting, embedded with other metal or non-metallic materials, both to save assembly hours and to save metal.

Read recommendations:

aluminium extrusion square tube

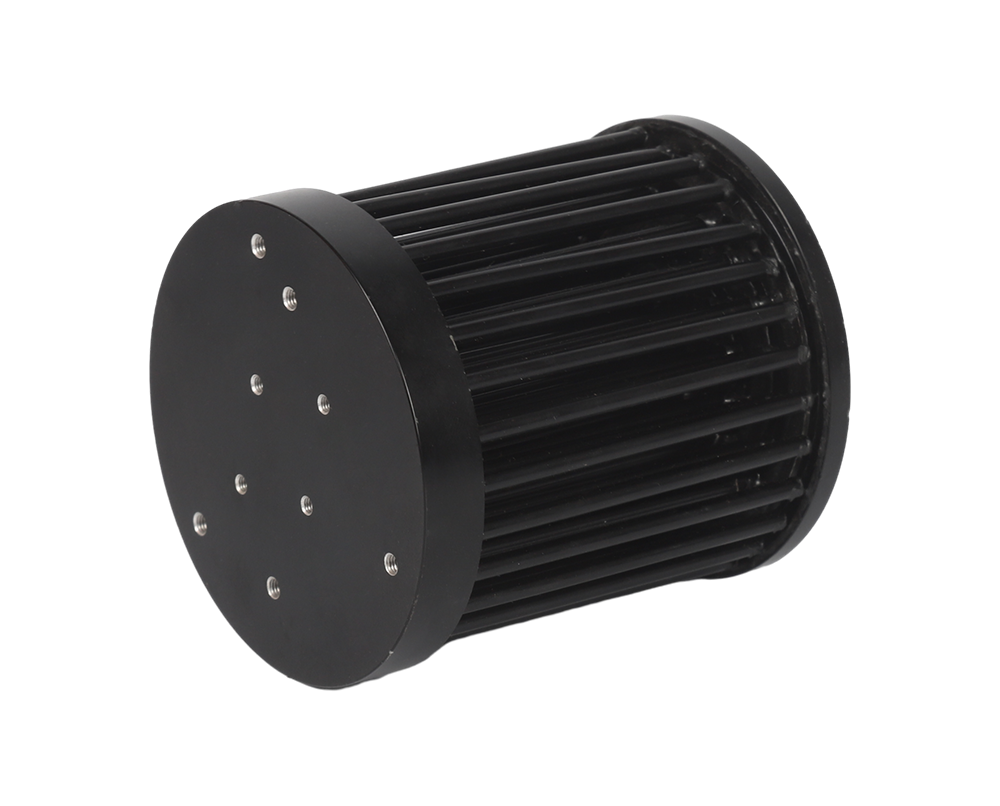

LED Cold Forged Downlight Radiator

round aluminum extrusion profiles

metal injection molding companies

Hygiene of Aluminum Die - Castings in Food Processing Equipment

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible