2024-03-13 hits:0 source:News

1, aluminum and aluminum alloy have a high affinity for oxygen, easy to generate oxide film, and this layer of oxide film once removed will produce a new layer of oxide film in a very short time, seriously affecting the binding force of the coating.

2, the electrode potential of aluminum is very negative, and it is easy to replace metal ions with more positive potential when immersed in the plating solution, affecting the binding force of the coating.

3, the expansion coefficient of aluminum and aluminum alloy is larger than other metals, so it is not suitable for electroplating in the range of large temperature changes. The difference between the expansion coefficient of aluminum and aluminum alloy and other metal coatings will cause greater stress, so that the binding force between the coating and aluminum and aluminum alloy is not strong.

4, aluminum is an amphoteric metal, soluble in acids and bases, and unstable in acidic and alkaline electroplating solutions.

5, aluminum alloy die casting parts have sand holes, pores, residual plating solution and hydrogen, easy to bubble, will also reduce the binding force between the coating and the base metal

Read recommendations:

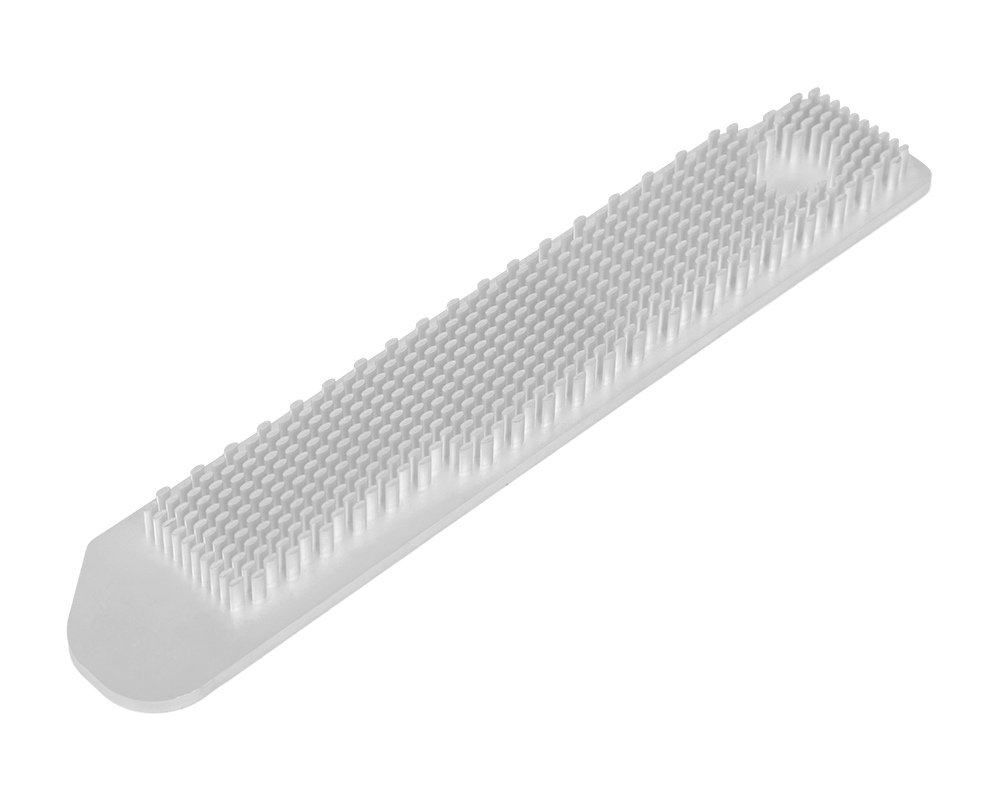

Large Aluminum Cold Forged Pin Fin Radiator

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible