2024-03-01 hits:0 source:News

Before electroplating zinc alloy die-casting parts, pre-treatment is important because whether it can be processed well will affect the quality of electroplating. If not handled properly, it will cause rework or scrapping of zinc alloy die castings, thereby increasing the scrap rate. So during the electroplating process, there are some things that we need to pay attention to

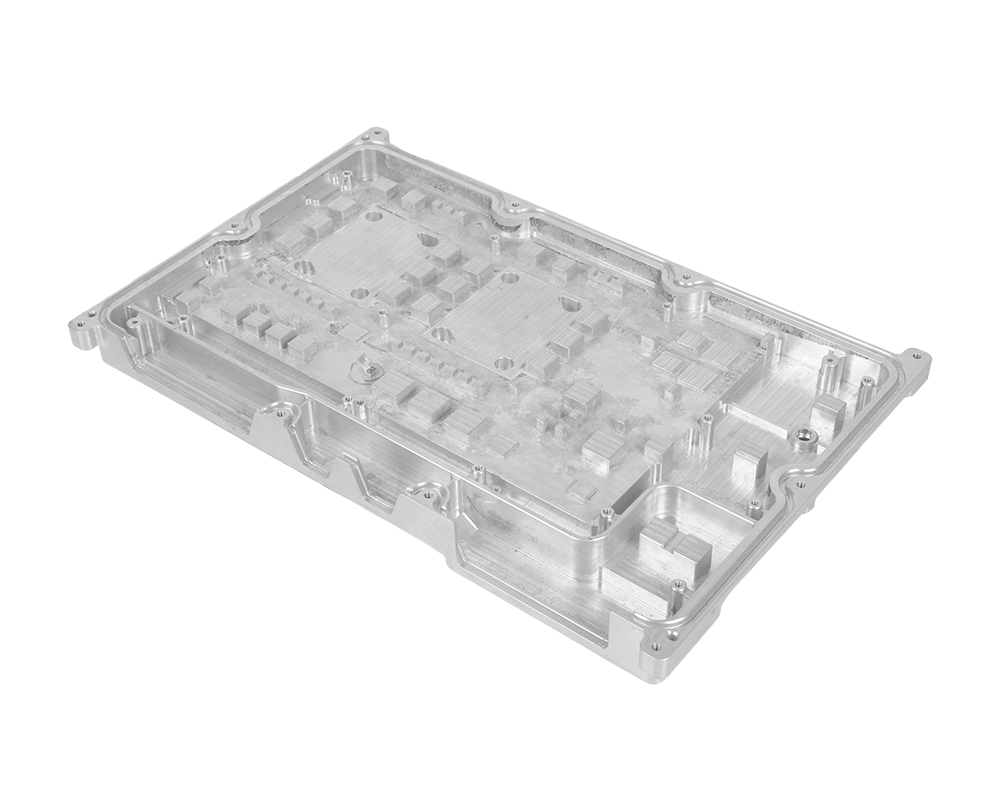

Firstly, it is necessary to understand the structural characteristics of zinc alloy die castings

On the surface of zinc alloy die castings, there is a smooth and dense metal layer, with a loose and porous structure below. When polishing zinc alloy die-casting parts, we should be careful not to break the dense layer on the surface of the workpiece, otherwise it will cause blistering, peeling and other phenomena on the coating.

Secondly, master the chemical properties of zinc alloy die castings

During the process of oil removal or etching, strong acid or alkali should be used. If the plating solution infiltrates the substrate and is not cleaned thoroughly, it will cause blistering and peeling of the coating during the electroplating process, which will affect the yield of zinc alloy die castings. Therefore, strong acid or alkali should not be used.

Thirdly, accelerate the connection speed between pre-treatment and electroplating of zinc alloy die-casting parts

After removing the oil stains and oxide film on the surface of zinc alloy die-casting parts, the parts should be immediately placed in the electroplating bath for processing

Electroplating is used to prevent the surface from regenerating into oxide films or hydrates, which can affect the adhesion between coatings.

Read recommendations:

2020 aluminum extrusion profile

automotive metal stamping suppliers

Aluminum Profile Extrusion Speed Control

Discussion on Surface Treatment Process of Zinc Alloy Die Castings

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible