2024-02-26 hits:0 source:News

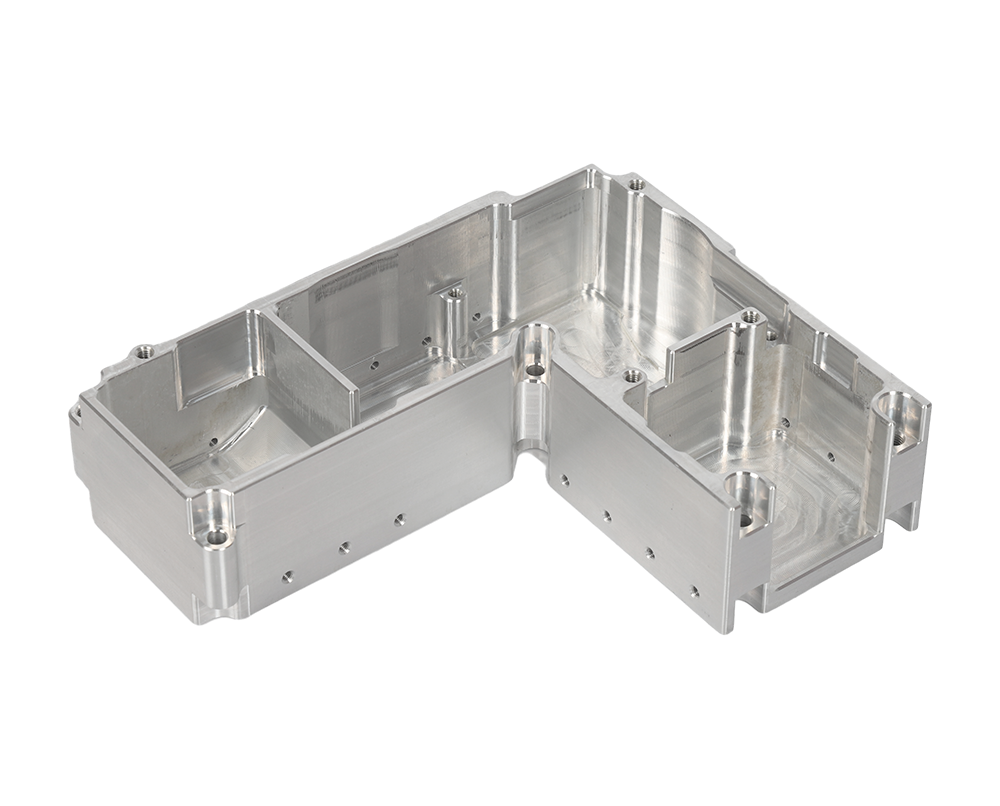

With the development of the aluminum alloy die-casting industry, the defective products produced by aluminum alloy die-casting manufacturers are called scrap, which are unqualified products. The occurrence of these problems will greatly increase the production cost of aluminum alloy die-casting, and also bring great inconvenience to the process of aluminum alloy die-casting. Only by controlling the defect rate of aluminum alloy die-casting parts can production costs be reduced from the source. So let me share with you how we improve the defect rate of our products from several aspects:

1. Raw materials: Choosing aluminum alloy raw materials is really crucial. Choosing high-quality materials can greatly reduce the rate of defective products. Imported high-quality materials are used, which have strong corrosion resistance and uniform overall density. As a result, the quality of the die-casting blank will be relatively smooth.

2. Make defective products appear on the surface: Any appearance of defects must have an inherent cause. Only by solving each cause of defects can we truly achieve zero defects and make customers truly satisfied.

3. Quality control: Each process will be controlled by a dedicated person for comprehensive inspection. For example, polishing QC and outsourcing QC will be double checked to ensure that customers receive satisfactory aluminum alloy die-casting products. Every product and every product requires a full inspection to ensure that the product reaches the customer's hands and assembly is more worry free. At the same time, it can also help our customers improve production efficiency!

Read recommendations:

New energy battery shell aluminum extrusion parts manufacturer

40 x 40 aluminium profile price

The Key to Passivation and Corrosion Resistance of Aluminum Alloy Die Castings

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible