2024-01-17 hits:0 source:News

Those who believe in the decompression casting industry know that before the production of zinc alloy die-casting, molds need to undergo heat treatment. However, few people know that heat treatment can affect the quality of zinc alloy die-casting products. In fact, if you want to improve the quality of zinc alloy die-casting products, starting with heat treatment will be twice the result with half the effort!

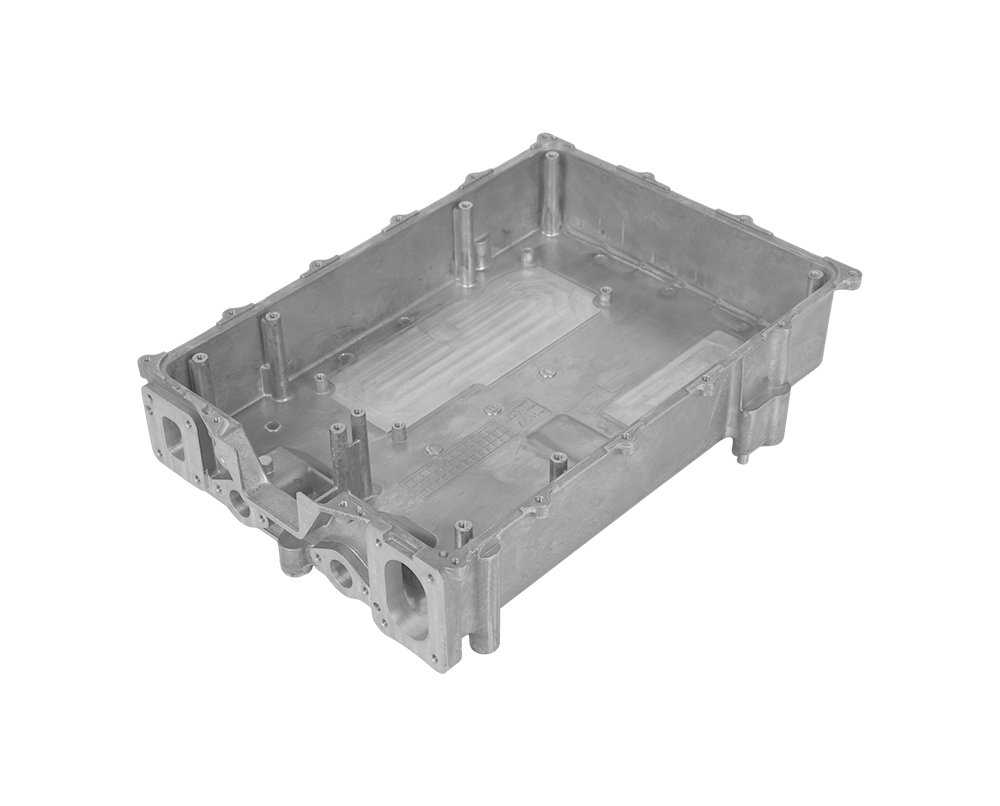

Firstly, the quality of the surface of aluminum alloy die castings is mainly determined by the acid washing process after heat treatment. If the surface of the product is uneven after oxidation and the degree of acid erosion of the metal during the acid washing process is different, the resulting product surface will be uneven. Therefore, heat treatment in the early stage of die casting is crucial, and the correct method must be used to heat treat the mold to ensure a smooth surface of the subsequent die cast product.

The above is a small technique for improving the quality of zinc alloy die-casting products, so often, the quality of a factory depends on the factory's control over product details.

Read recommendations:

What to do if there are pores in aluminum alloy die castings

What to do if there is a cold lap on the surface of zinc alloy die-casting parts

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible