2024-09-12 hits:0 source:News

Die cast aluminum and CNC aluminum have their own advantages and disadvantages in different application scenarios, making it difficult to simply judge which one is better.

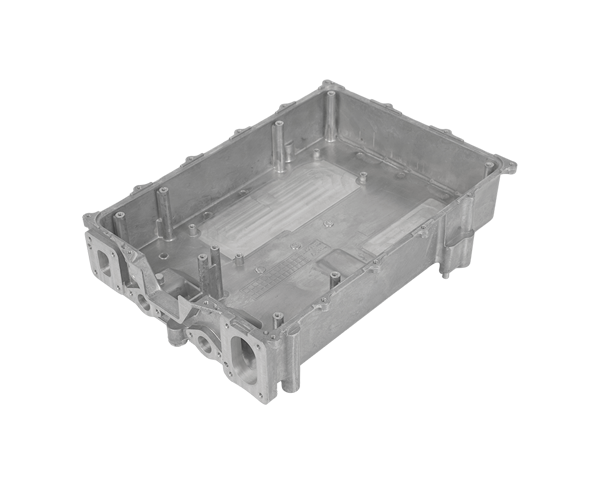

Die casting aluminum is a manufacturing process that involves injecting molten aluminum into a mold and forming it under pressure. Its advantage lies in the ability to produce complex shaped parts, with high production efficiency and low cost. The dimensional accuracy of die cast aluminum parts is relatively high, and the surface quality is also good, which can be subjected to some simple post-processing. For example, in the manufacturing of automotive parts, die cast aluminum can quickly produce complex shaped components such as engine housings and transmission housings, meeting the needs of large-scale production.

However, die cast aluminum also has some limitations. Due to the fast cooling rate of aluminum liquid during the die-casting process, defects such as porosity and shrinkage may exist inside the parts, affecting their mechanical properties. In addition, the material of die cast aluminum is relatively brittle and not suitable for applications that can withstand high-intensity impacts and vibrations.

CNC aluminum is made by cutting aluminum blocks through a computer numerical control machining center. Its advantage lies in the ability to achieve high-precision machining, which can meet the extremely high requirements for dimensional accuracy and surface quality in application scenarios. CNC machining can perform complex shape machining according to design requirements, and can precisely control the machining process to ensure stable quality of parts. For example, in the aerospace field, CNC aluminum parts are widely used in key parts such as aircraft structural components and engine components, which require extremely high precision and reliability of the parts.

However, the cost of CNC machining is relatively high and the processing time is also long. For large-scale production, the efficiency of CNC machining may not be comparable to that of die cast aluminum. In addition, CNC machining generates a large amount of chips that require effective processing and recycling to reduce their impact on the environment.

In summary, both die cast aluminum and CNC aluminum have their own advantages and disadvantages, and the selection should be comprehensively considered based on specific application needs. If it is necessary to produce parts with complex shapes and large quantities, and the mechanical performance requirements are not particularly high, die cast aluminum may be a better choice. If the precision and quality requirements for parts are extremely high, or if small-scale, customized production is needed, CNC aluminum is more suitable.

Read recommendations:

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible