2024-01-18 hits:0 source:News

In recent years, with the improvement of casting technology and casting quality in China, the casting industry has also been increasingly recognized and approved by enterprises. New orders are constantly coming in, and the production of zinc alloy die castings in China is also increasing year by year. However, many problems have arisen in the production of zinc alloy die castings, and cracks are one of them. So how to solve them?

1. Harmful impurities such as lead, tin, iron, and cadmium in the alloy exceed the specified range

2. The casting is removed from the model too early, resulting in insufficient metal strength

3. The extraction or ejection of the core is subjected to uneven force, resulting in one side being less stressed and the other side being more stressed, causing cracks and deformation of the product

4. The transition at the junction of casting wall thickness is severe

5. The melting temperature is too high, resulting in coarse grains

Solution:

1. The proportion of alloy materials should pay attention to the impurity content and not be too high

2. Extend mold opening time

3. Adjust the core and push rod to ensure even force distribution

4. Change the uneven section of wall thickness

Read recommendations:

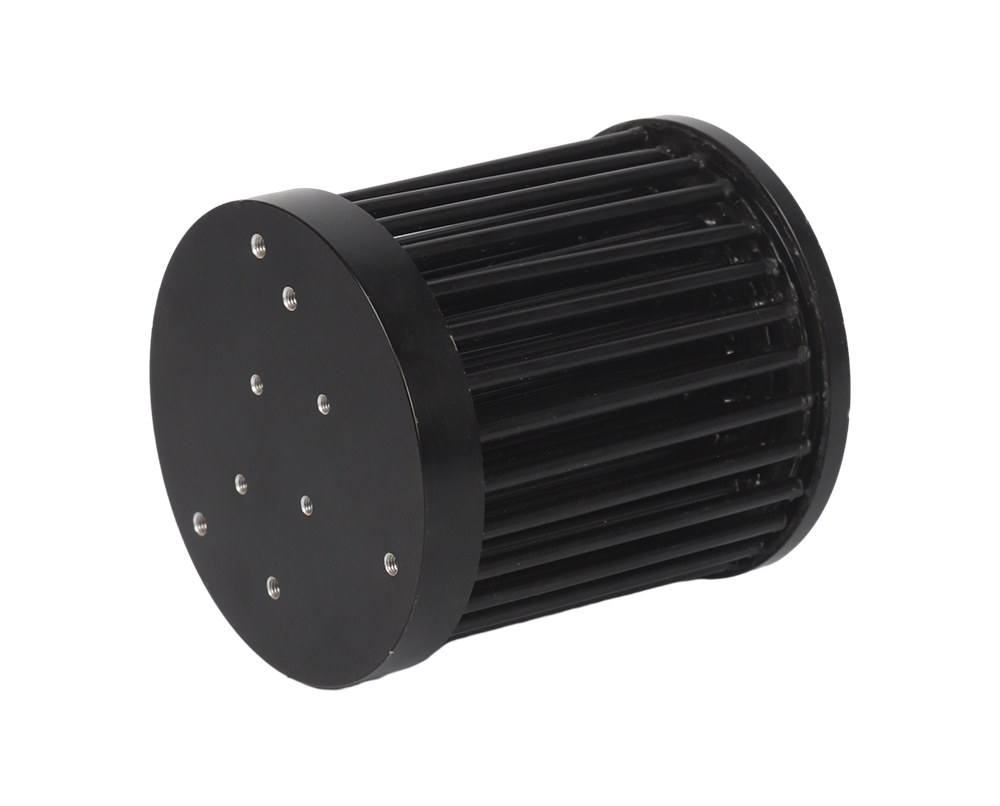

Aluminum Multiport Adapter Housing

pvc injection molding wholesale

Preservation Performance of Aluminum Die - Castings in Smart Refrigerators

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible