2023-12-22 hits:0 source:News

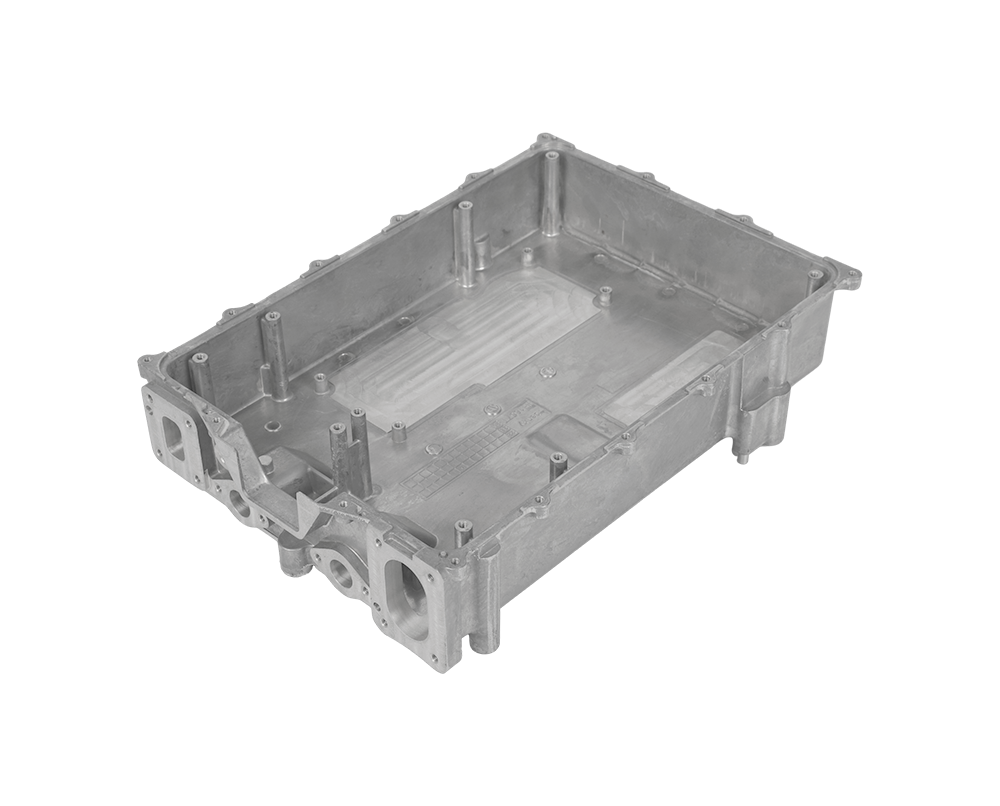

Aluminum alloy die castings are mechanical components with low manufacturing costs, strong plasticity, and light weight, and their surface treatment is crucial for their performance and service life. Improving the wear resistance of aluminum alloy die castings is crucial in surface treatment.

The following are several surface treatment methods that can improve the wear resistance of aluminum alloy die castings:

1. Anodization

Anodizing is one of the most commonly used surface treatment methods to improve the wear resistance of aluminum alloy die castings. It increases its hardness and wear resistance by forming an oxide film on the surface of aluminum alloy. This oxide film has good corrosion resistance, insulation and decorative properties, and can also increase the surface roughness of the die casting and improve lubrication.

2. Electroplating

Electroplating is another commonly used surface treatment method to improve the wear resistance of aluminum alloy die castings. It can form a layer of metal or alloy coating on the surface of aluminum alloy, thereby increasing its surface hardness and wear resistance. For example, electroplating with materials such as nickel, chromium, and cobalt can effectively improve the wear resistance of aluminum alloy die castings.

3. Spray painting

Spray coating is a simple and feasible surface treatment method to improve the wear resistance of aluminum alloy die castings. It can form a coating on the surface of aluminum alloy to prevent direct contact with the external environment, making it more durable. For example, using materials such as polyurethane and epoxy resin for spraying can effectively improve the wear resistance of aluminum alloy die castings.

4. Grinding

Grinding is a method of treating the surface of aluminum alloy die castings through cutting, polishing, and other methods. It can remove defects such as unevenness, unevenness, and burrs on the surface of aluminum alloys, thereby increasing their surface hardness and wear resistance. In addition, grinding can also improve the surface quality and aesthetics of aluminum alloy die castings.

Read recommendations:

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible