2023-12-19 hits:0 source:News

We all know that common surface treatments for zinc alloy die-casting include electroplating, baking paint, sandblasting, electrophoresis, etc. However, the most commonly used process is electroplating. So what is electroplating? What are the types of electroplating? Let me tell you.

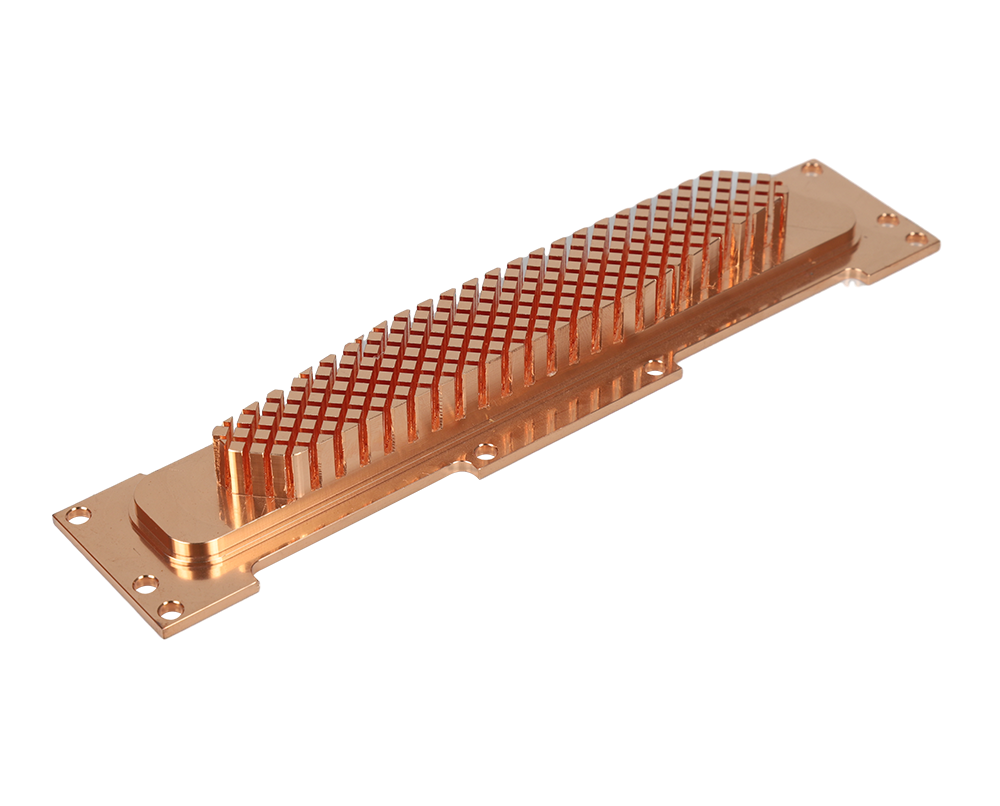

Electroplating is the process of using electrolysis to deposit metal or alloy on the surface of a workpiece, forming a uniform, dense, and well bonded metal layer, which is called electroplating.

Electroplating can also be divided into the following types: ① Water plating has a wide variety of colors, which can be determined based on the color palette provided by the customer; ② Vacuum plating can also be determined based on the color palette; ③ Electroplating and wire drawing can be customized with red antique copper, blue antique copper, white chromium, nickel color, and gun color; ④ Electroplating can also be combined with other processes to customize the process according to customer needs.

Read recommendations:

aluminium bullnose stair nosing

precision stamping distributors

Processing of aluminum alloy die-casting parts.7075 t6511 extrusion

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible