2024-10-28 hits:0 source:News

Die-cast aluminum components often require surface treatment to enhance their appearance, durability, and corrosion resistance. There are several common surface treatment processes for die-cast aluminum.

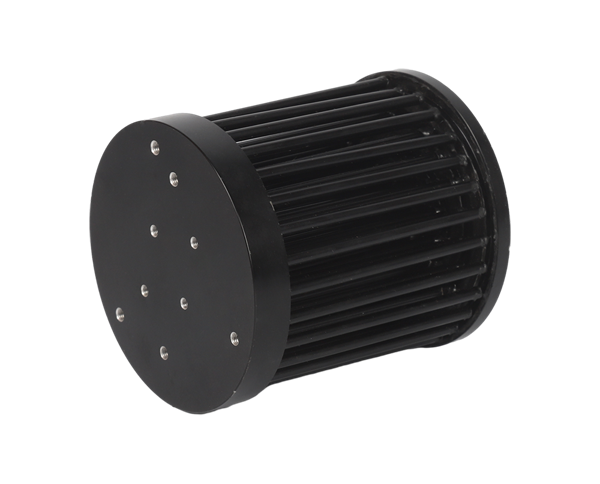

One of the most popular methods is anodizing. In this process, the aluminum part is immersed in an electrolytic bath, and an electrical current is passed through it. This causes the formation of a protective oxide layer on the surface of the aluminum. The thickness of the oxide layer can be controlled, and different colors can be achieved by adding dyes to the bath. Anodized surfaces are highly resistant to corrosion and abrasion, and they have a smooth, attractive finish.

Powder coating is another common surface treatment for die-cast aluminum. In this process, a dry powder is electrostatically sprayed onto the surface of the part. The powder is then cured in an oven, forming a hard, durable coating. Powder coatings come in a wide variety of colors and finishes, and they offer excellent resistance to chipping, fading, and corrosion.

Electroplating is also used to coat die-cast aluminum parts. In this process, the part is immersed in a bath containing a metal salt solution, and an electrical current is passed through the bath. This causes the metal ions in the solution to deposit onto the surface of the aluminum, forming a thin metal coating. Electroplated coatings can provide enhanced corrosion resistance, wear resistance, and electrical conductivity.

Painting is a simple and cost-effective surface treatment for die-cast aluminum. The part can be sprayed with a variety of paints, including enamel, lacquer, and polyurethane. Painting can provide good protection against corrosion and abrasion, and it can be used to achieve a wide range of colors and finishes.

In addition to these methods, there are other surface treatment processes for die-cast aluminum, such as chemical conversion coatings, polishing, and buffing. The choice of surface treatment depends on the specific requirements of the application, such as the desired appearance, durability, and corrosion resistance.

Read recommendations:

2020 t slot aluminum extrusion

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible