2024-12-03 hits:0 source:News

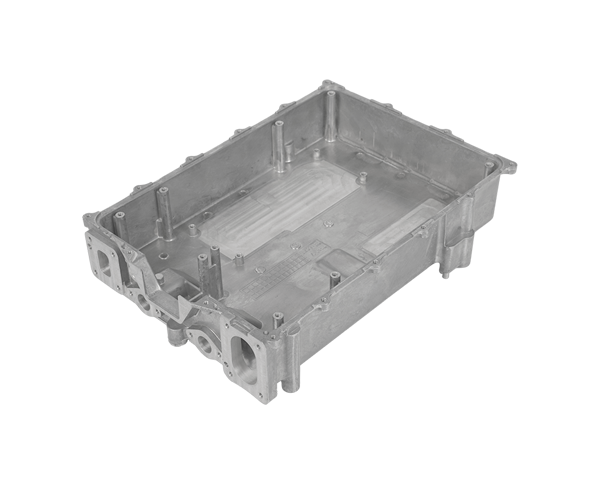

Die casting mold structural processes involve several key steps and techniques. Machining is a fundamental process. The mold cavity and other components are precisely machined using advanced CNC (Computer Numerical Control) machines. This ensures high dimensional accuracy and surface finish. For example, milling, drilling, and grinding operations are carried out to create the complex geometries of the mold cavity and the runner system. Heat treatment is another crucial aspect. After machining, the mold components are heat-treated to improve their hardness, toughness, and wear resistance. This helps the mold withstand the high temperatures and pressures during the die casting process.

Surface treatment is often applied. Coating the mold surface with materials like nitride or chrome can enhance its corrosion resistance and reduce friction. This is especially important as the molten metal comes into contact with the mold. Assembly of the mold is a complex process. It requires careful alignment and fitting of various components such as the cavity inserts, cores, and ejector systems. The assembly must be precise to ensure proper functionality. Additionally, testing and debugging are essential. The mold is tested for leaks, proper metal flow, and ejection of the casting. Any issues are identified and corrected during this stage. The design of the runner and gating system is also a part of the structural process. It is optimized to control the flow rate and direction of the molten metal, ensuring uniform filling of the mold cavity and minimizing defects. The cooling channels' design and layout are determined based on the heat transfer requirements to achieve efficient solidification of the casting. these structural processes work together to create a high-quality die casting mold that can produce accurate and defect-free castings.

Read recommendations:

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible