2024-12-25 hits:0 source:News

Die-casting alloy materials play a crucial role in modern manufacturing, enabling the production of complex and high-precision components. There are several common types of die-casting alloys. Zinc alloys are widely used due to their excellent fluidity, which allows for the creation of intricate shapes with fine details. They have good mechanical properties and are relatively easy to cast, making them suitable for various applications such as automotive parts, hardware, and consumer electronics.

Aluminum alloys are another popular choice. They offer a good combination of strength, light weight, and corrosion resistance. Different aluminum alloy formulations are available, each with its own set of properties, making them adaptable to diverse industries like aerospace, automotive, and machinery. Magnesium alloys are also utilized, known for their extremely low density, which results in lightweight components. They are often used in applications where weight reduction is a critical factor, such as in the production of laptop housings and some automotive components.

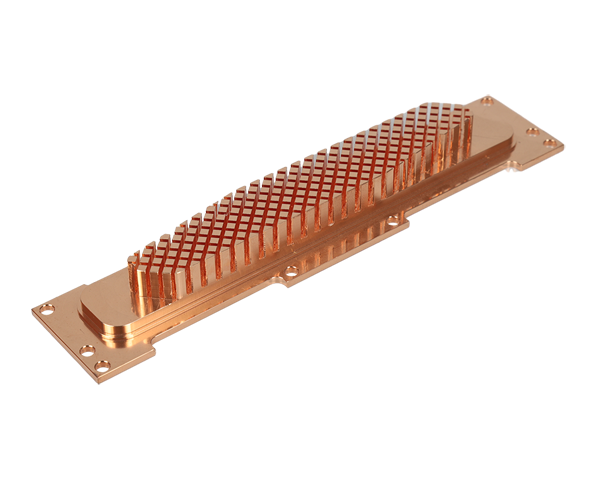

Copper alloys possess excellent thermal and electrical conductivity, along with good mechanical strength. They are commonly employed in electrical connectors, plumbing fixtures, and some industrial machinery parts. These alloys can be further enhanced with the addition of other elements to modify their properties according to specific manufacturing requirements. The selection of the appropriate die-casting alloy depends on factors such as the desired mechanical properties, cost, weight limitations, and the intended application of the final product.

Read recommendations:

precision sheet metal stamping

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible