2023-12-25 hits:0 source:News

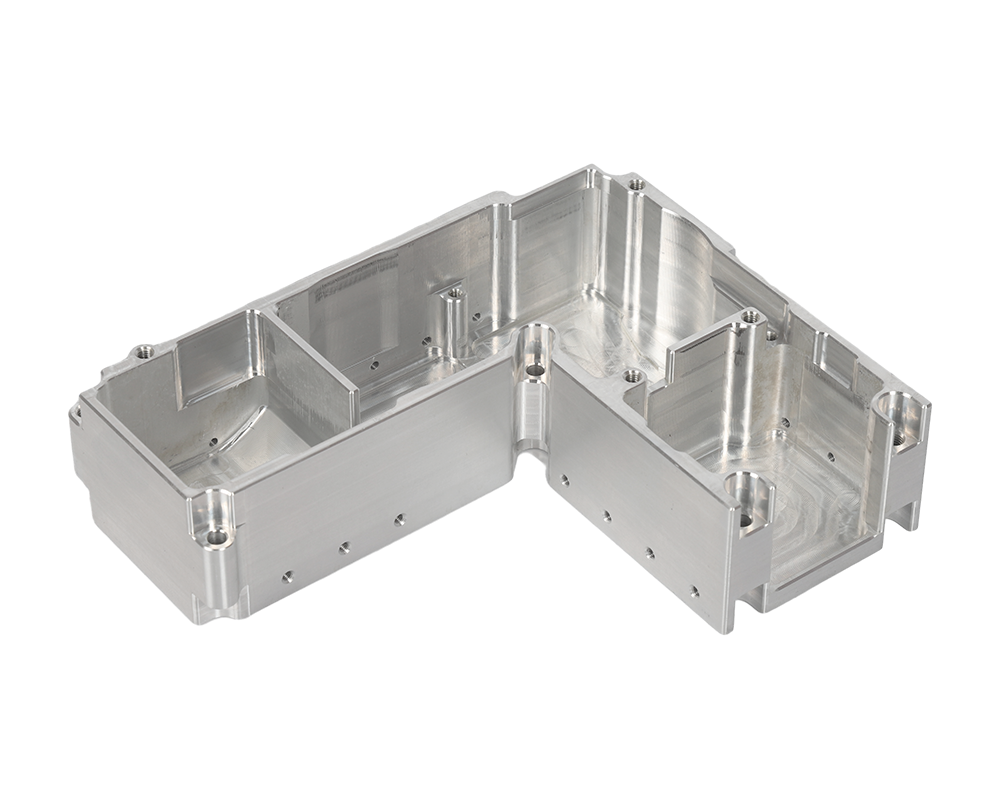

Due to the appearance issues such as mold lines, burrs, and other burrs on the surface of aluminum alloy die-casting parts during the die-casting production process, burrs can have a significant impact on the quality of the die-casting parts. Therefore, deburring is an important process in die-casting. What are the methods for deburring aluminum alloy die-casting plants?

1. Using CNC machining, edge cutting machines, punching machines, etc. to remove burrs, this method can efficiently remove burrs.

2. Manual deburring has high flexibility, but it is easy to damage the die casting and has low efficiency.

3. Using sandblasting machine or sanding belt machine for polishing, these two methods are suitable for handling deep hole burrs that cannot be manually or mechanically processed.

4. Manual pneumatic tools, files, and other deburring methods are more efficient than manual labor.

Read recommendations:

aluminum extrusions for screen enclosures

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible