2024-06-04 hits:0 source:News

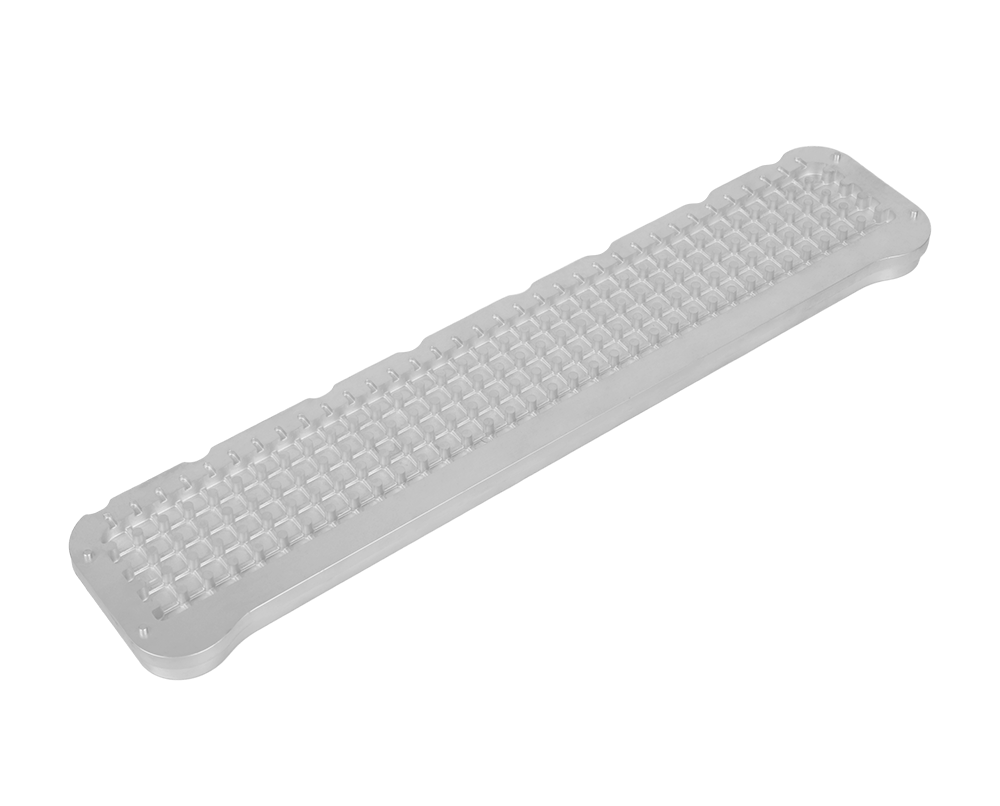

In the production process of aluminum alloy die-casting parts, some customers may require that the hardness of the aluminum alloy die-casting parts produced must meet a certain standard, especially for products with high hardness requirements. If it is difficult to produce according to ordinary process requirements, then the hardness of the aluminum alloy die-casting parts you make has not met the customer's requirements. Which link has the problem?

Just recently, we received a customer who wanted to customize mechanical parts with a hardness of over 150. However, in the products we have produced before, the hardness did not meet this requirement. After comprehensive discussion and testing by our technical personnel, it has been found that as long as the heat treatment is done properly, the hardness of the product can meet the customer's standards. In fact, the low hardness of aluminum alloy die-casting products is due to the fact that the products have not undergone solid solution treatment. If they undergo heat treatment, and the heat treatment temperature is higher and the insulation time is longer, the hardness will decrease.

So if you want to make high hardness aluminum alloy die castings, reasonable and effective treatment in the production process of aluminum alloy die castings can improve the hardness of aluminum alloy die castings!

Read recommendations:

glass and aluminum company profile

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible