2024-01-10 hits:0 source:News

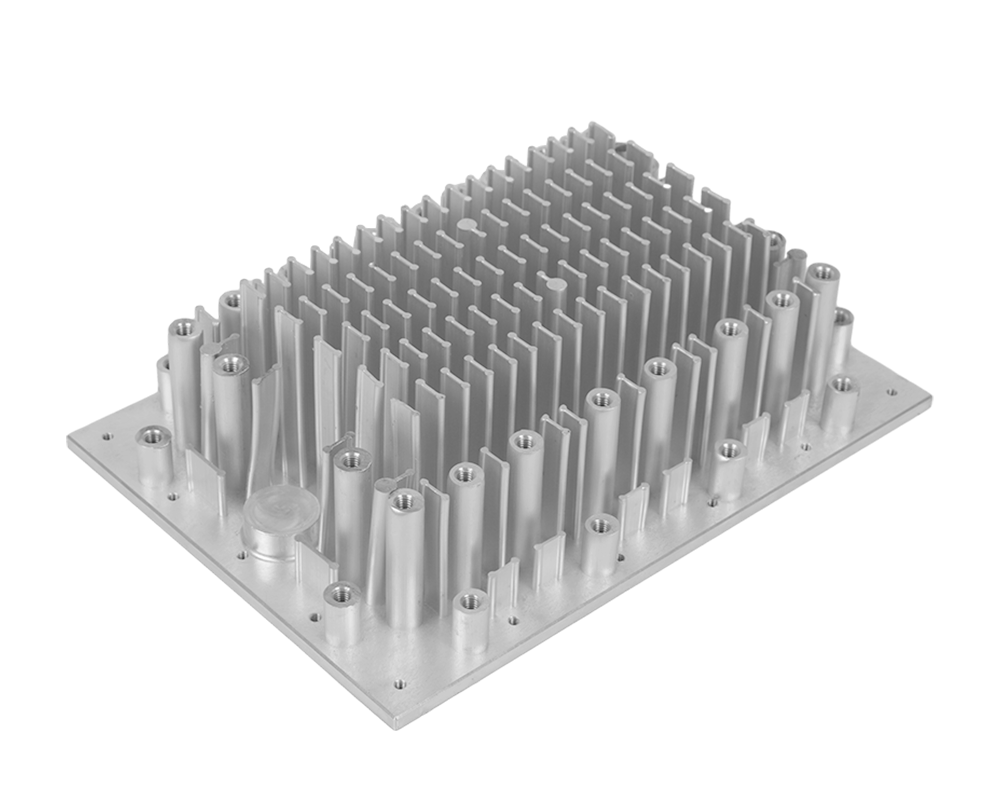

Zinc aluminum alloy die-casting manufacturing has excellent die-casting and mechanical functions, and is widely used in traditional industries such as mechanical parts, hardware parts, locks, toys, etc. However, zinc alloy also has electrical and thermal conductivity, vibration damping characteristics, and electromagnetic shielding functions. Therefore, it is constantly used in electronic, telecommunications, and household appliances, especially in some electronic products that need to handle electromagnetic shielding.

It is precisely because zinc aluminum alloy has some functional advantages compared to other metals, and is environmentally friendly and renewable, it can replace some heavily polluting metals, greatly improving the utilization rate of metal products. It can also provide some cost control.

In summary, the future development potential of zinc aluminum alloy die-casting is still very huge, and the manufacturing of zinc aluminum alloy die-casting will also be carried out in the direction of their respective functional advantages.

Read recommendations:

aluminium channel powder coated

aluminium profile construction

stock aluminum extrusion profiles.What factors affect the cost of zinc alloy die-casting

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible