2024-01-04 hits:0 source:News

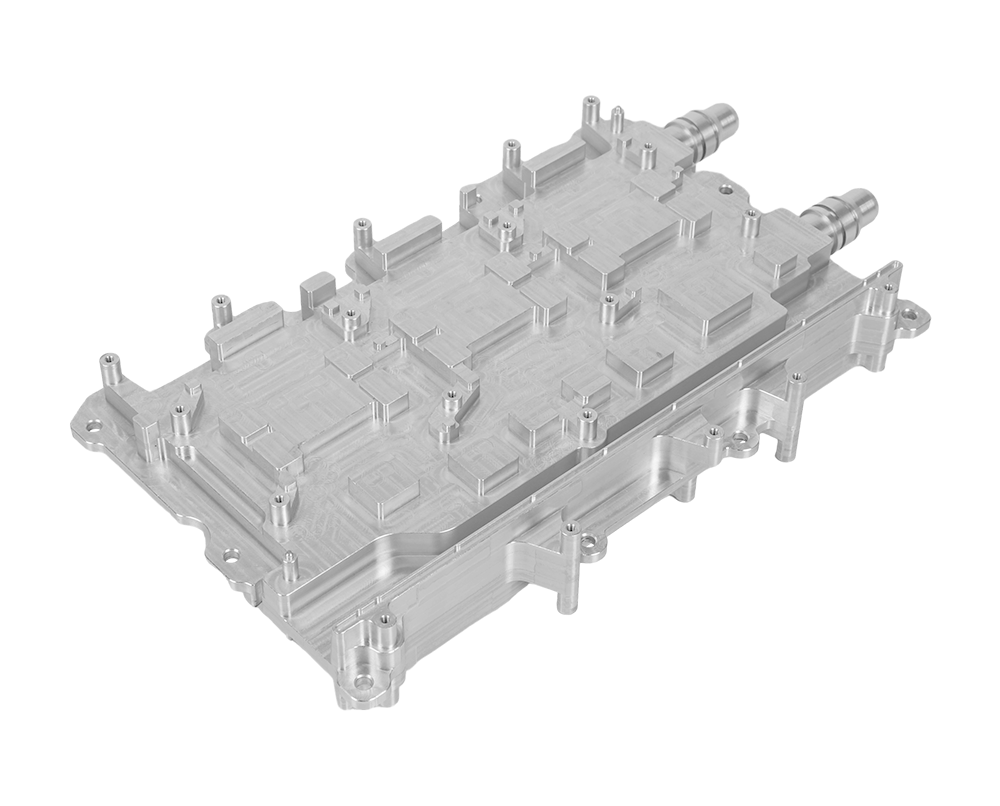

Aluminum alloy die-casting mold is a mechanical die-casting machine that uses a pre cast casting mold to heat aluminum or aluminum alloy into a liquid state and pour it into the feeding port of the die-casting machine. After being die-casting by the die-casting machine, aluminum parts with the shape and size limited by the mold are cast. Such parts are usually called aluminum alloy die-casting.

A common problem encountered is that controlling the surface temperature of aluminum alloy die-casting molds is crucial for producing high-quality die-casting parts. Uneven or inappropriate die casting mold temperatures can also lead to unstable casting dimensions, resulting in defects such as thermal pressure, mucous membranes, surface depressions, internal shrinkage cavities, and hot bubbles during the production process.

Due to the excellent fluidity and plasticity of metal aluminum and aluminum alloys, aluminum alloy die casting can produce various complex shaped products, as well as achieve high precision and smoothness. This greatly reduces the mechanical processing amount of castings and the casting allowance of metal aluminum or aluminum alloys, not only saving electricity and metal materials, but also greatly saving labor costs.

In addition, aluminum alloy die-casting molds have excellent thermal conductivity, small weight, and processability, and are widely used in various industries such as automotive manufacturing, power construction, and building decoration.

Read recommendations:

bosch rexroth extruded aluminum

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible