2024-03-12 hits:0 source:News

Zinc alloy die casting in the casting process by raw materials, molds, equipment and other factors, the blank will appear the phenomenon of tip burr, so how to deal with these situations? Zinc alloy die casting processing plant to answer your questions!

1, the general method of removing the tip is artificial removal, which is a more traditional blank processing method, mainly using sandpaper, file, belt sander, grinding and other tools to remove, more suitable for smaller tip processing.

2, die to tip is also a more common method, this method requires a certain amount of mold manufacturing costs, and even need to manufacture plastic mold, the use of die with die to remove the rough parts of the tip burr, etc., more suitable for the structure of more simple die casting, remove the efficiency of artificial high, the effect is better than artificial.

3, grinding to remove the tip burr, mainly with ultrasonic vibration, roller, sandblasting, and other ways, more die casting manufacturers use this method, more suitable for large die-casting products mass input processing. However, there will be some residual corners and corners that are not clean, and the subsequent need for manual treatment and other ways to remove.

Read recommendations:

40 x 40 aluminium profile price

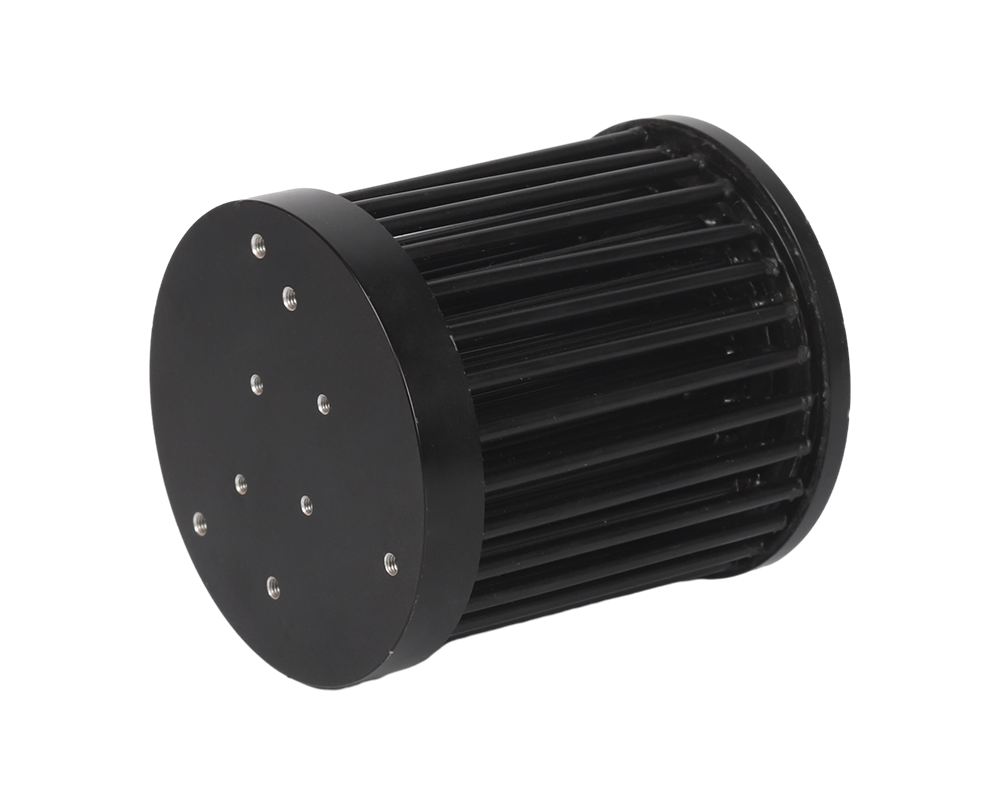

aluminum extrusion tube profiles

aluminum parts for electric vehicles.Zinc alloy die casting shortening hole how to "cure"

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible