2024-05-09 hits:0 source:News

Aluminum alloy die-casting molds are necessary tools for making aluminum alloy die-casting parts, and are vessels for forming die-casting parts, which have a direct impact on the production of die-casting parts. Having good aluminum alloy die-casting molds may not necessarily lead to good products being die-casting; But without good die-casting molds, it is impossible to produce good products through die-casting.

The production of aluminum alloy die-casting molds requires rich experience and technology. Experienced die-casting manufacturers will avoid certain situations when producing aluminum alloy die-casting molds, such as the inability to have deep holes, which are generally achieved through post-processing; For example, the wall thickness difference of the die casting cannot be too large. Excessive wall thickness difference can lead to stress concentration, resulting in deformation, porosity, shrinkage and other problems of the die casting; For example, the structure of aluminum alloy die-casting molds should not be too complex, otherwise poor filling may occur.

Read recommendations:

schluter rondec outside corner

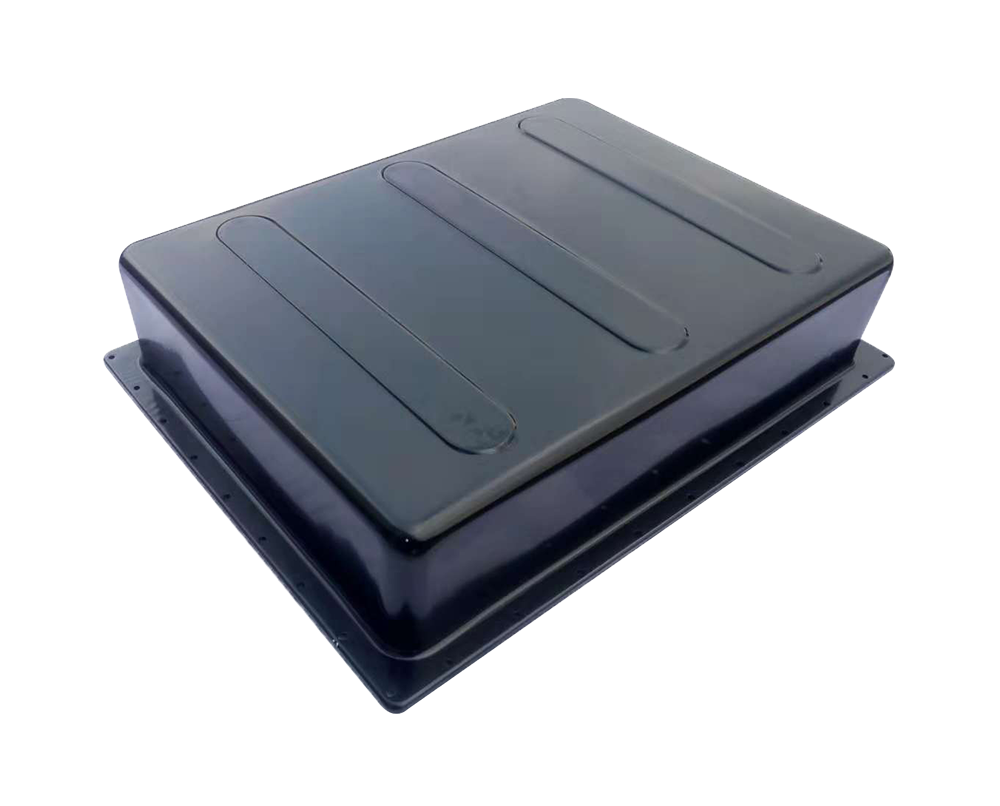

Die - Cast Aluminum Components for Surveillance and Security Systems

The entire process flow of die-casting processing.medical device injection molding

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible