2024-01-12 hits:0 source:News

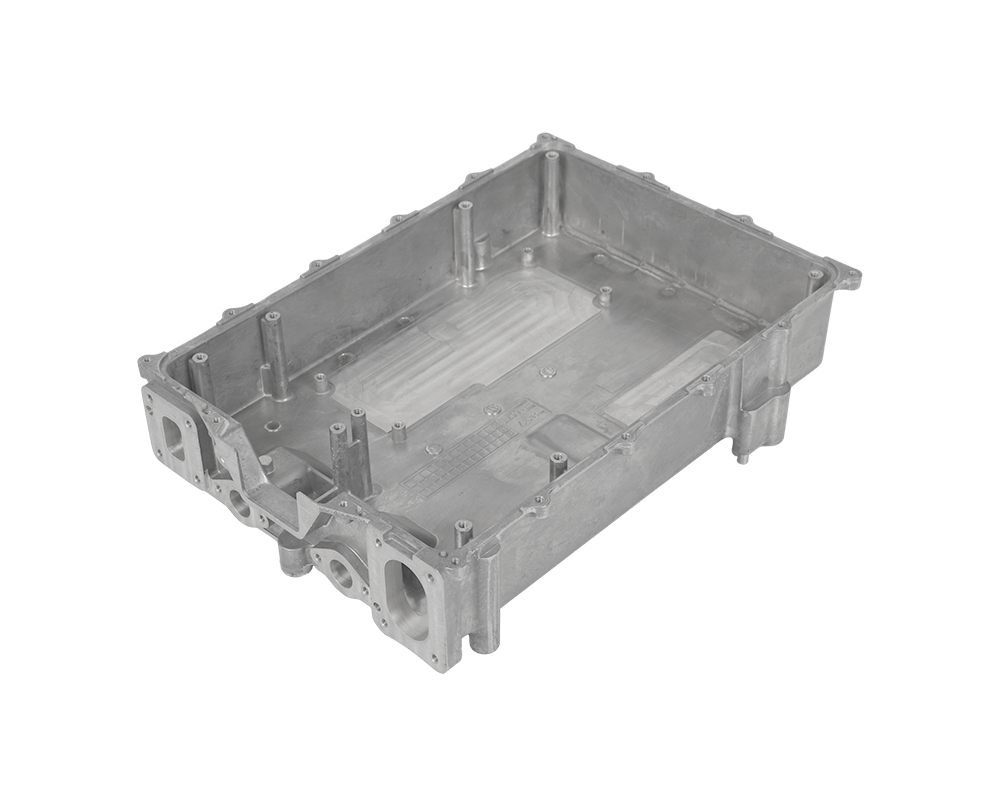

Aluminum alloy die-casting parts are applied in various industries, and the market demand is huge. However, in the production process, aluminum alloy die-casting parts are prone to shrinkage problems. Today, aluminum alloy die-casting factories will explain the reasons and solutions for this problem.

Shrinkage is a hole caused by insufficient internal compensation during the condensation process of die castings, and the reasons are as follows

① Pouring temperature too high

② Low injection pressure

③ Castings have areas or sections with significant metal accumulation or changes in cross-section on the structure

④ Small inner gate

Solution to shrinkage

① Change the structure of castings, eliminate metal aggregation and significant cross-sectional changes

② Reduce the pouring temperature under possible conditions

③ Increase injection pressure

④ Properly improve the pouring system to better transmit pressure

Read recommendations:

custom precision metal stamping.Opinions of die-casting companies on die-casting processes

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible