2024-09-03 hits:0 source:News

Life is full of endless problems waiting for you to solve one by one, and the same goes for zinc alloy die-casting factories. In the process of die-casting production, there are always big and small problems. So today, let's talk about the solution to the problem of blackening on the surface of zinc alloy die-casting parts!

The surface of zinc alloy die-casting parts turns black, especially after machining, appearing as black spots and black spots. This situation may be due to insufficient pressure during die-casting and insufficient density of the workpiece, resulting in the formation of capillary pores. These capillary pores absorb water and are oxidized, leading to this problem. So, we still need to start with the die-casting process to solve the problem. In addition, impurities, release agents, etc. can also cause this situation on the blank surface. If you must use surface treatment methods to eliminate (mask) it.

So under normal circumstances, zinc alloy die-casting parts will undergo surface treatment, such as electroplating, baking paint, sandblasting, powder coating, passivation and other surface treatment processes. The products treated by these processes have exquisite appearance, rich and colorful colors, mainly corrosion resistance and oxidation resistance, which not only ensures the quality of die-casting products, but also makes zinc alloy die-casting parts more beautiful!

Read recommendations:

aluminium window frame profiles

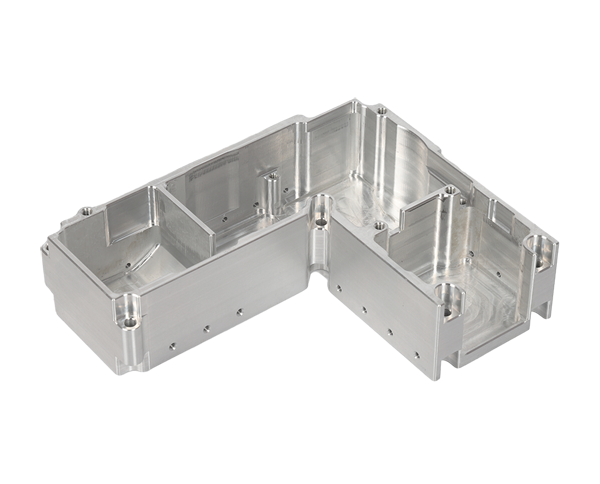

aluminum electronic enclosures boxes

The treatment method for scratches caused by defects in aluminum alloy die-casting molds

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible