2025-04-12 hits:0 source:News

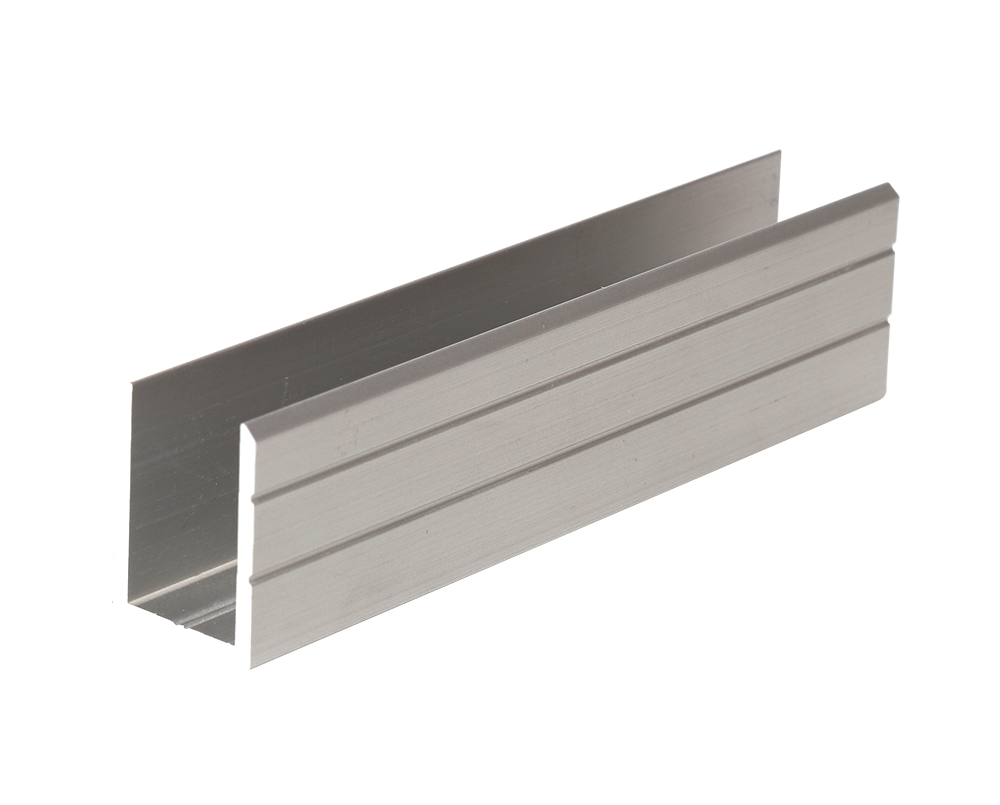

1024 pure aluminum profiles are crafted from high - purity aluminum, with aluminum content typically reaching up to 99.24%. This high - purity composition endows them with several distinct properties.

In terms of physical properties, 1024 pure aluminum profiles have a relatively low density, approximately 2.7 g/cm³. This makes them lightweight, which is highly advantageous in applications where weight reduction is crucial, such as in the aerospace and transportation industries. Despite their low density, they still possess good strength - to - weight ratios. They are malleable and ductile, allowing for easy shaping through various manufacturing processes like extrusion, rolling, and forging. This malleability enables the creation of complex profiles with different cross - sectional shapes, meeting the diverse design requirements of different products.

Chemically, 1024 pure aluminum is highly resistant to corrosion in many environments. When exposed to air, a thin, self - healing oxide layer forms on its surface. This oxide layer acts as a protective barrier, preventing further oxidation and corrosion. However, in highly acidic or alkaline environments, the corrosion resistance may be compromised. In such cases, additional surface treatments like anodizing can be applied to enhance its corrosion resistance.

Thermally, 1024 pure aluminum profiles are excellent heat conductors. They can quickly transfer heat, which is beneficial in applications such as heat sinks in electronic devices. In a heat sink, the aluminum profile efficiently dissipates heat generated by electronic components, helping to maintain the optimal operating temperature of the device and prevent overheating.

Electrically, pure aluminum has good electrical conductivity, although it is not as conductive as copper. Nevertheless, it is still widely used in electrical applications where cost - effectiveness and weight are important factors, such as in power transmission lines.

The mechanical properties of 1024 pure aluminum profiles can be further adjusted through processes like cold working and heat treatment. Cold working, such as rolling or drawing, can increase the strength of the aluminum by introducing dislocations in the crystal structure. Heat treatment, on the other hand, can be used to relieve internal stresses or improve the ductility of the material.

Read recommendations:

aluminium extrusion square tube

aluminum window frame extrusions

How to judge whether aluminum alloy die castings are of high quality

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible