2024-05-07 hits:0 source:News

In the process of producing die castings, aluminum alloy die-casting plants need to establish multiple inspection processes to ensure the quality of the products. As a one-time formed product, the inspection of the newly cast blank is crucial because if the aluminum alloy die-casting plant cannot detect defective products at this time, the losses will increase and it will also affect the recovery.

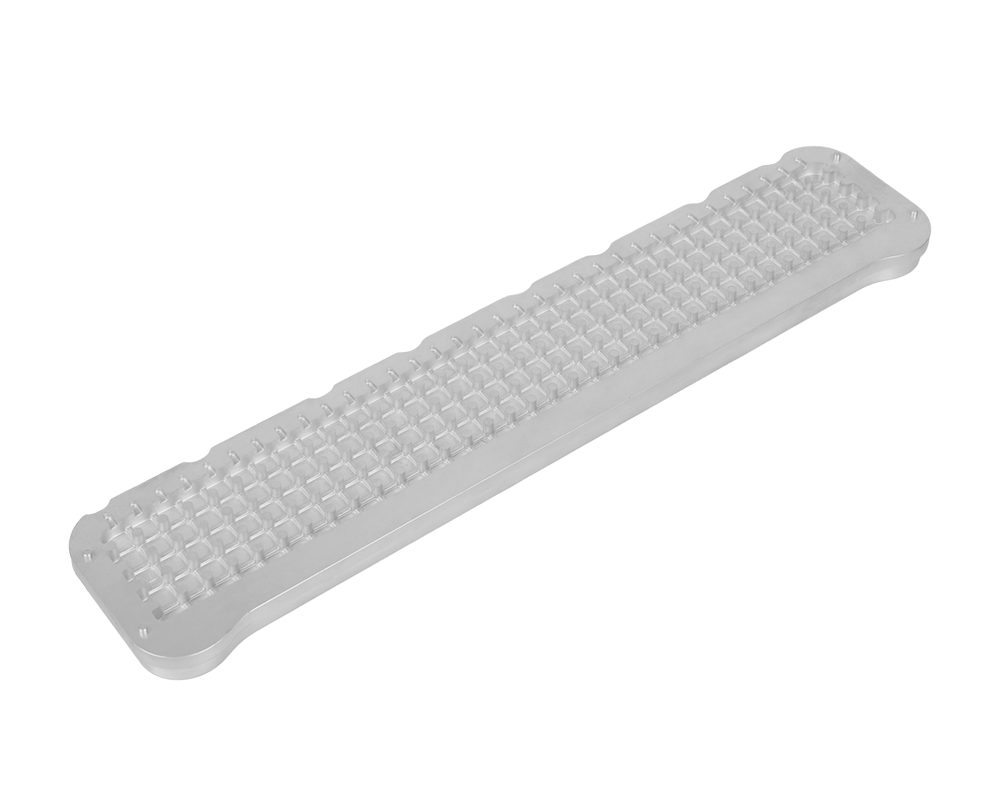

When inspecting die castings in an aluminum alloy die casting factory, the first thing to check is the integrity of the product appearance. There should be no under casting, cracks, bubbles, looseness, or any penetrating defects. For defects such as scratches, dents, missing flesh, and network burrs, they should comply with the regulations negotiated between the aluminum alloy die casting factory and the customer. Then, the gate, flash, overflow port, and top rod marks of the die casting should be cleaned thoroughly, and the remaining marks should be within the size specified by the aluminum alloy die casting factory.

In addition to the inspection of raw materials, aluminum alloy die-casting plants also conduct incoming material inspection, inspection after tapping and sharpening, inspection after polishing, inspection after surface treatment, and visual inspection during packaging. Through various inspections, aluminum alloy die-casting plants ensure the quality of products and the interests of customers.

Read recommendations:

Environmental Protection Measures in Aluminum Alloy Die - Casting Process

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible