2024-03-12 hits:0 source:News

At present, from the recent orders received by the aluminum alloy die casting factory, a lot of consumer electronics accessories and shells want to improve the process, with aluminum alloy material to do, originally looking at the increase in customers of customized aluminum alloy die casting, aluminum alloy die casting factory should be happy, but in the face of the process that customers need to do, aluminum alloy die casting factory is worried!

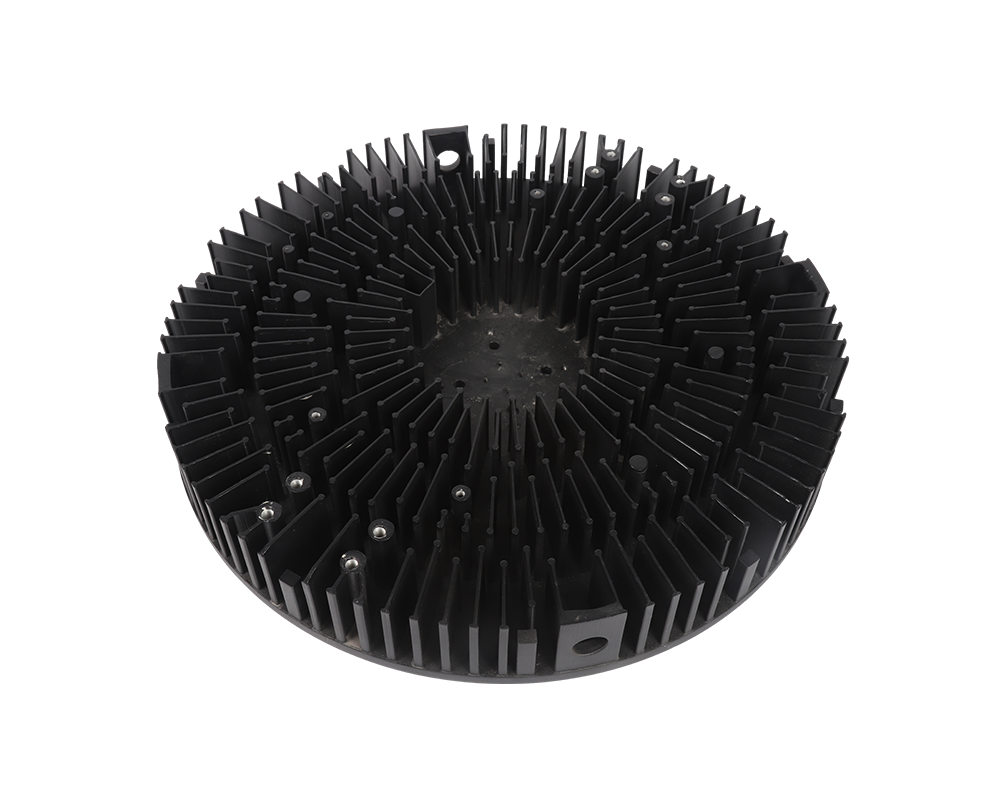

Due to the low density of aluminum alloy material, light weight, high strength, good rigidity, stable size and strong pressure resistance and heat dissipation, it is widely used, such as smart wear, Bluetooth speakers, digital products, aviation, automotive and other fields, but at present, aluminum alloy die-casting factory received a lot of consumer electronics orders to use aluminum alloy die-casting process to do. The surface treatment needs to be customized according to customer needs, at present, aluminum alloy die casting surface treatment technology urgently needs to improve, in order to make the appearance standard like zinc alloy die casting, the defective rate is still relatively high, so the cost is relatively high, there is no advantage. In the face of the upcoming new situation, aluminum alloy die casting plant needs to urgently improve the surface treatment technology of aluminum alloy die casting, take the initiative to meet the new trend of aluminum alloy electronic products die casting customization, and enjoy the highlight moment of aluminum alloy die casting customization!

Read recommendations:

universal t track aluminum extrusion for woodworking

small aluminum electronic enclosures

Aluminum alloy shell processing cost revealed, are you losing money?

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible