2023-12-21 hits:0 source:News

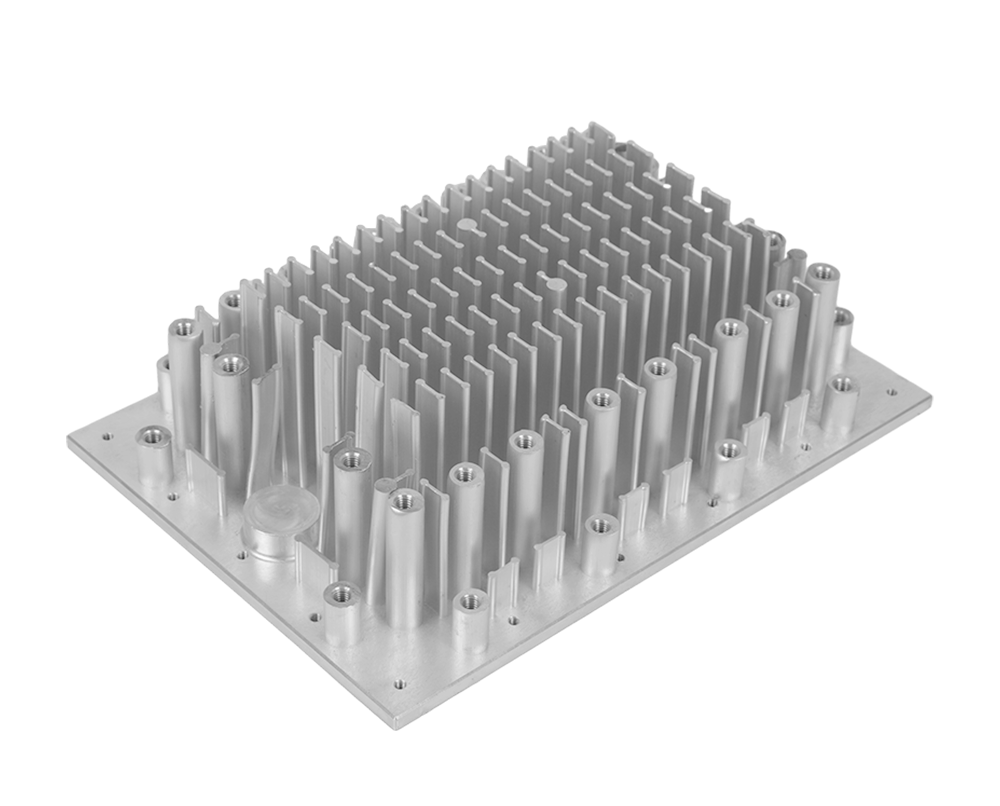

Zinc alloy die-casting has a wide range of applications, which can be seen in electronic products, communication and other fields. Zinc alloy die-casting has become a relatively mature process today, but there are still some areas that need improvement.

Shortening holes are a defect in the zinc alloy die-casting process. The small holes that appear inside or on the surface of the die-casting part due to the volume reduction of the molten metal during the solidification process are called shortening holes. They can affect the quality of the subsequent processes of the die-casting part, such as forming bubbles during the surface treatment of the die-casting part, which directly leads to the invalidation of the die-casting part and increases production costs. So, how to treat the shortening holes in zinc alloy die-casting?

At present, there is no way to completely "cure" this defect, and only reasonable measures can be taken to improve it. There are three methods: ① to make the die-casting parts cool as evenly as possible; ② Improve the pouring system; ③ Reasonably planning the structure of die castings can effectively improve the problem of shortened holes in zinc alloy die casting.

Read recommendations: