2024-03-28 hits:0 source:News

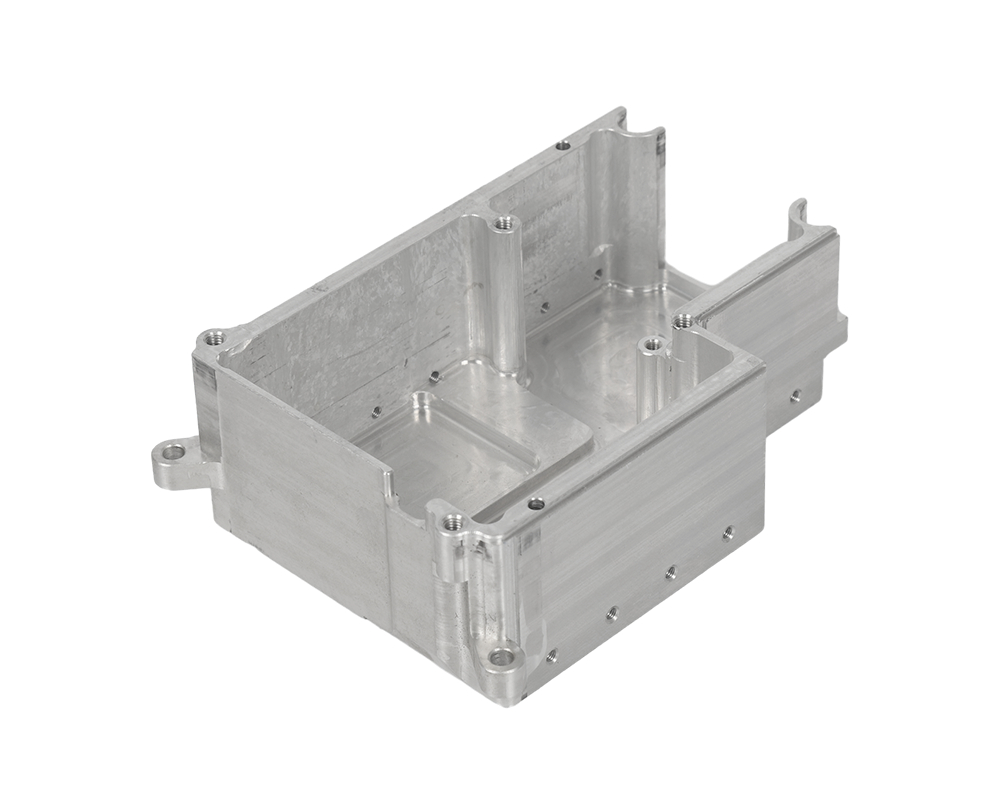

There will always be all kinds of die-casting defects in the production of die-casting aluminum castings, at this time, it is necessary to find all kinds of defects through inspection means, so that different solutions are used according to different defects to ensure the quality of die-casting parts, then how to check the defects of die-casting aluminum castings?

Casting defect inspection generally adopts appearance inspection, chemical analysis inspection, mechanical property inspection, macro inspection, non-destructive inspection and other inspection methods, and then we will be divided into two inspection methods, respectively, internal defect inspection and appearance defect inspection.

I. Internal defect inspection

1, ultrasonic inspection: the use of ultrasonic reflection principle for inspection, through ultrasonic inspection can be found pores, cracks, shrinkage, inclusion and other defects.

2, pressure inspection: the water, oil and other media immersed in the sealed die-casting cavity, if there is leakage phenomenon can detect the location of the defect.

2. Inspection of appearance defects

Using magnifying glass and other tools to observe with the naked eye, check whether there are defects on the surface of the die casting, such as cracks, pores, etc.

Read recommendations:

custom aluminium extrusion cost

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible