2024-01-16 hits:0 source:News

The working conditions of aluminum alloy die-casting molds are different from other molds. Generally, they need to work at around 500 degrees Celsius. In addition to being subjected to high pressure, they also need to withstand high temperature effects. Therefore, for the steel used for aluminum alloy die-casting molds, aluminum alloy die-casting factories still need to have certain requirements when choosing:

1、 Excellent cutting performance

To extend the service life of cutting tools, enhance cutting performance, and reduce surface roughness, the hardness of steel used in plastic molds must be appropriate to avoid excessive tool consumption for aluminum alloy die-casting plants.

2、 Good thermal stability

The shape of aluminum alloy die casting molds is often complex and difficult to process after quenching. It is recommended to choose parts with good thermal stability. When the aluminum alloy die casting mold is formed and processed through heat treatment, due to the small coefficient of linear expansion, small heat treatment deformation, and small size change rate caused by temperature differences, the metallographic structure and mold size are stable, and processing can be reduced or no longer carried out to ensure the accuracy of mold size and surface roughness requirements.

3、 Good polishing performance

High quality aluminum alloy die castings require a small roughness value on the surface of the mold cavity. The selected steel should have minimal impurities, uniform microstructure, and no fiber directionality. During polishing, there should be no pitting or orange peel like defects.

4、 Sufficient surface hardness and wear resistance

During the operation of the mold, due to the high pressure and friction that the filling and flow of aluminum alloy liquid must withstand, it is required that the mold maintain the stability of shape accuracy and dimensional accuracy to ensure sufficient service life of the mold.

Read recommendations:

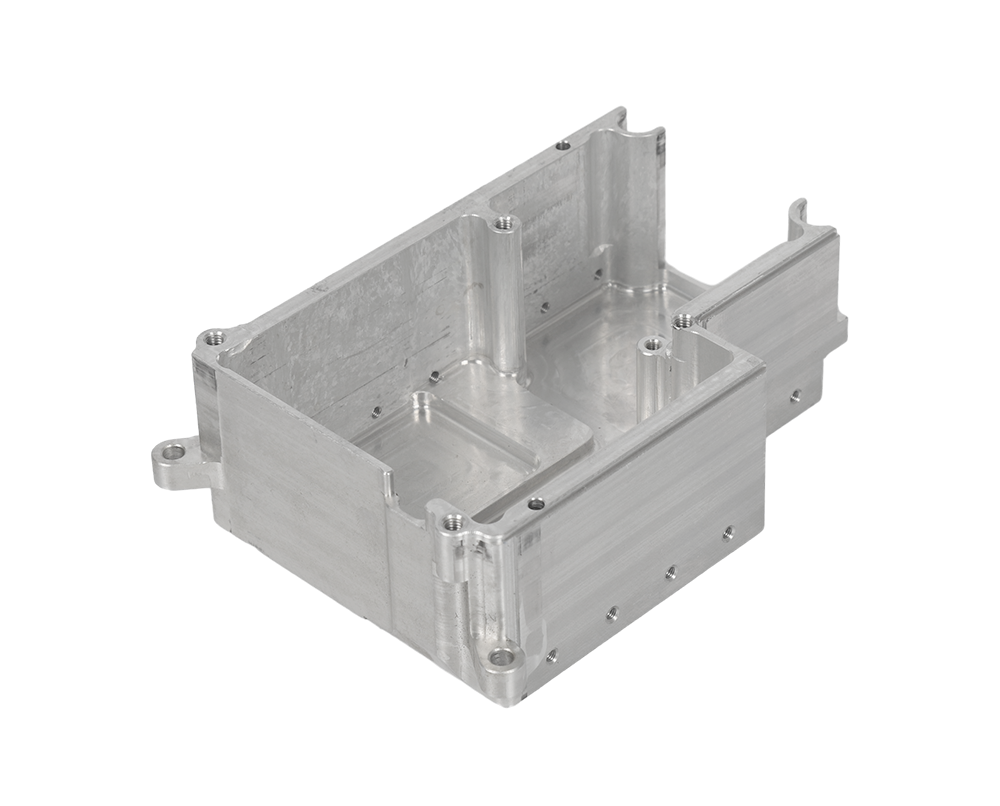

High Precision Mechanical Housing

zinc pressure die casting Factory

sheet metal heating ducts.Flow mark defects during die-casting processing

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible