2024-09-27 hits:0 source:News

The heating system of die-casting molds plays a crucial role in the die-casting production process.

Die casting is a process of injecting molten metal into a mold cavity under high pressure, allowing it to rapidly cool and form. The temperature of the mold has a significant impact on the quality and production efficiency of die-casting products. The main purpose of the heating system is to ensure that the mold operates within the appropriate temperature range.

A good heating system can achieve rapid heating and shorten the preparation time before production. Before starting the die-casting process, heating the mold to a suitable temperature can reduce the cooling rate of the molten metal in the mold cavity, thereby improving the fluidity of the metal and allowing the die-casting product to better fill the cavity, reducing the occurrence of defects such as cold shut and porosity.

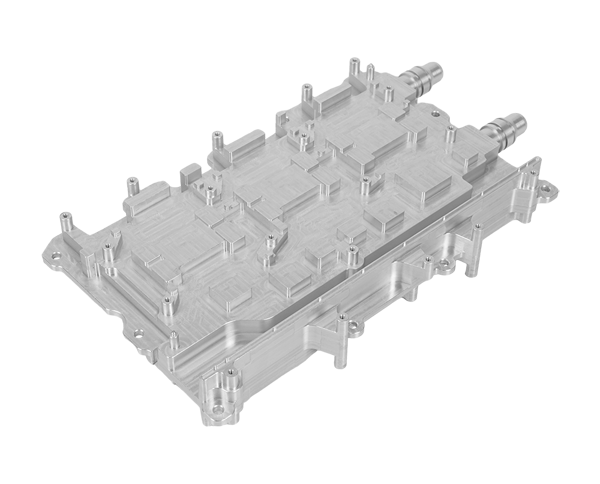

Heating systems usually use electric heating methods, such as heating rods, heating plates, etc. These heating elements are evenly distributed in key parts of the mold, such as the mold cavity, flow channel, etc., to ensure the uniformity of the mold temperature. At the same time, the heating system is equipped with temperature sensors and controllers, which can accurately monitor and control the temperature of the mold, keeping it within the set range.

In practical applications, the design of heating systems needs to consider multiple factors. Firstly, the structure and size of the mold require different heating layouts depending on the shape and size of the mold. Secondly, there are the types and process requirements of die-casting metals. Different metals have different melting points and flowability, requiring different mold temperatures. In addition, it is necessary to consider the reliability and safety of the heating system to ensure that there will be no malfunctions or safety hazards during long-term use.

In short, the heating system of die-casting molds is an indispensable part of die-casting production. It can improve the quality and production efficiency of die-casting products, bringing greater economic benefits to die-casting enterprises.

Read recommendations:

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible