2024-09-09 hits:0 source:News

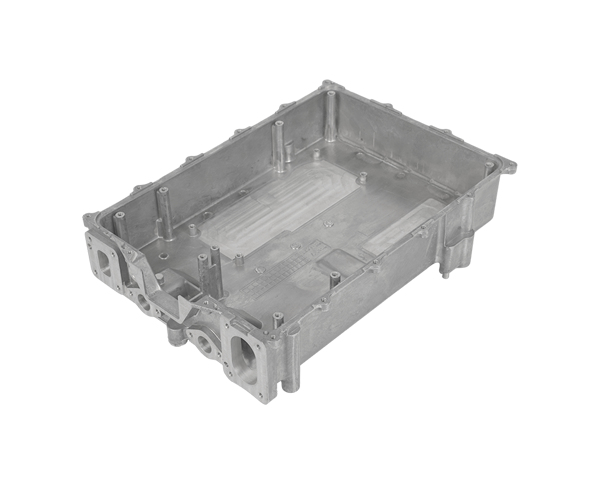

As a popular process for aluminum alloy die-casting, sandblasting technology is widely used in various aluminum alloy shell die-casting parts. To make exquisite aluminum alloy die-casting parts, the aluminum alloy shell processing sandblasting process needs to pay attention to the following four points:

Firstly, before sandblasting, the surface of the aluminum alloy die-casting shell needs to be cleaned thoroughly. The cleaning process involves using sulfuric acid to remove surface oil stains and dirt, followed by acid washing and neutralization with alkali;

Secondly, after pickling, air dry or dry the aluminum alloy shell die-casting parts to inspect the surface, mainly checking whether they are clean, whether there are watermarks, whether there is yellowing phenomenon, etc

Thirdly, sandblasting is the process of roughening the surface of aluminum alloy shells through the impact of high-speed sand flow. The types of sand particles used are generally between 80 # and 320 #, with larger values indicating smaller sand particles. The roughness of the sand particles on the surface of the aluminum alloy shell is determined by the type of sand particles and the size of the sandblasting pressure. Under the same pressure, the larger the sand particle value, the finer the surface; When the sand particle type is consistent, the greater the pressure, the rougher the surface.

Fourth, manual sandblasting and automatic sandblasting. The efficiency of manual sandblasting is relatively slow, and sometimes the spraying is uneven; Automatic sandblasting has high efficiency and uniform surface roughness.

The application of aluminum alloy die-casting industry is becoming more and more widespread, and more and more products are being replaced by aluminum alloy. In order to make aluminum alloy shell die-casting parts with exquisite appearance, a series of external surface treatments are also required. Sandblasting technology is quite common in the processing of aluminum alloy shells, and the treated effect is also deeply loved by consumers!

Read recommendations:

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible