2024-08-28 hits:0 source:News

In recent years, the development and application of aluminum alloy die-casting technology have received widespread attention. For a long time, in order to expand the application scope of aluminum alloy die-casting technology, people have been continuously developing some new and special die-casting methods.

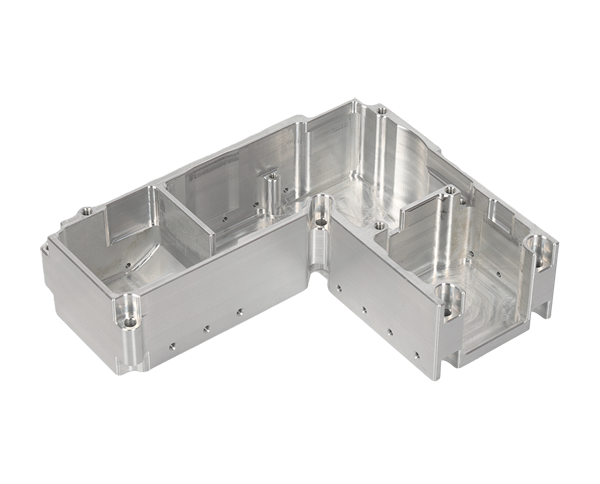

Due to the many characteristics of die-casting technology, it has shown great advantages in improving the accuracy level, production efficiency, surface technology, and other aspects of non-ferrous metal alloy die-casting parts. With the development of industries such as automobiles and motorcycles, as well as the realization of design requirements such as improving the quality of die-casting parts, saving energy consumption, and reducing pollution, the application scope of non-ferrous metal alloy die-casting parts, especially aluminum alloy die-casting parts, is rapidly expanding. Relevant data shows that the use of aluminum alloy die-casting parts instead of steel castings is becoming an important trend in industrial development countries. Currently, die-casting is one of the widely used processes for automotive parts, accounting for half of various automotive forming processes.

In the future, the die-casting process will adopt new technologies and high-tech equipment to improve the quality of die-casting parts and the service life of die-casting molds, opening up broader prospects for zinc aluminum alloy die-casting production.

Read recommendations:

custom extruded aluminum shapes

aluminium structural sections.Customized zinc alloy die castings

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible