2024-06-05 hits:0 source:News

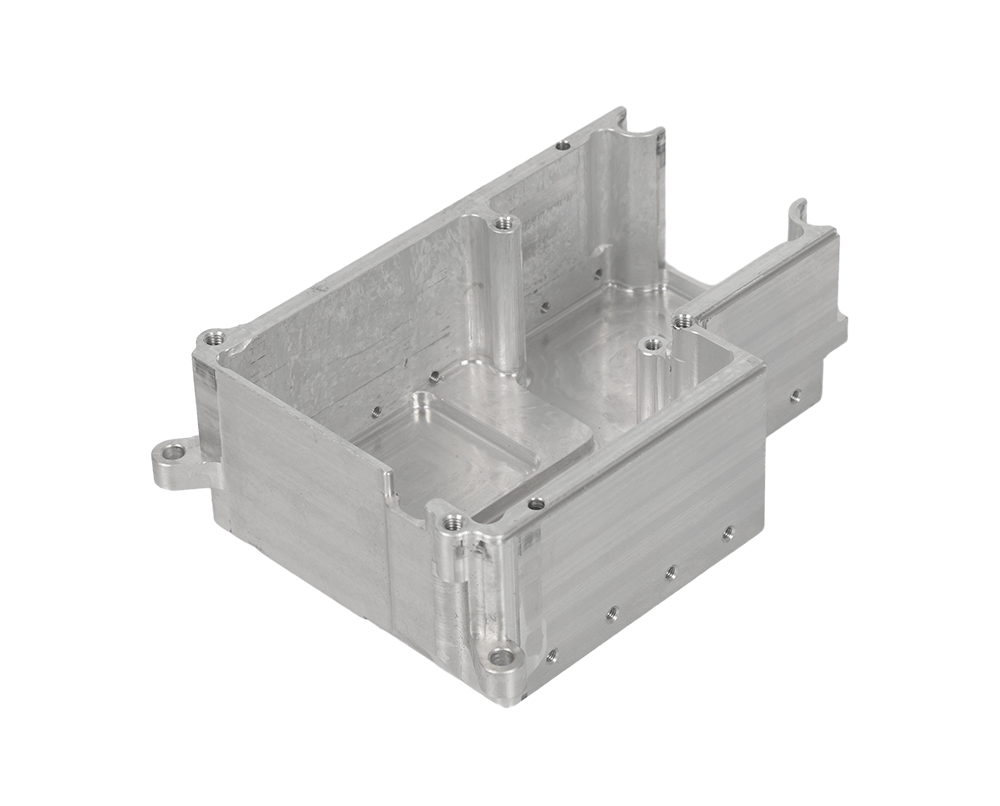

A complete die cast must be rough and contain excess material before completion, and in this case, the die casting company needs to take measures to clean the die cast.

The purpose of cleaning is to remove excess materials, burrs, and adhesive coatings. Therefore, during the die-casting process, the flow channel, overflow groove, and burrs should be removed. Punching equipment can be used to remove them, or manual removal can be used. However, punching equipment cannot completely remove them, and manual removal is needed as an auxiliary measure. During manual removal, the die-casting should not be damaged, and it should not cause defects or deformation. Alternatively, vibration grinding machines, centrifugal polishing machines, and other equipment can be used to remove burrs. Under the action of high-speed vibration or rotation, the burrs can be removed and polished by rubbing against the die-casting parts. When precision machining is required for die-casting products, a grinder or grinding wheel can be used to polish them. If the polishing is not in place, a file can be used to repair it.

Read recommendations:

aluminum electronic enclosures boxes

extruded aluminum channel shapes

desktop cnc machine for metal.Pattern of Defects in Zinc Alloy Die Castings

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible