2023-12-07 hits:0 source:News

The tonnage of the die-casting machine directly affects the locking force, which is crucial for maintaining the stability of the mold during the die-casting process. Insufficient locking force may cause the mold to not fully close, resulting in defects or unqualified castings.

2. Casting pressure: The tonnage of the die-casting machine determines the casting pressure that can be applied. Different casting pressures are required for different alloys and casting requirements. Machines with larger tonnage are usually able to provide higher casting pressure, suitable for a wider range of materials and processes. Machines with larger tonnage typically have larger injection capacity and shooting speed, which means they can complete each die-casting cycle faster,

3. Improve production efficiency. Machines with larger tonnage are usually more expensive, so when choosing a machine, it is necessary to balance tonnage, performance, and budget.

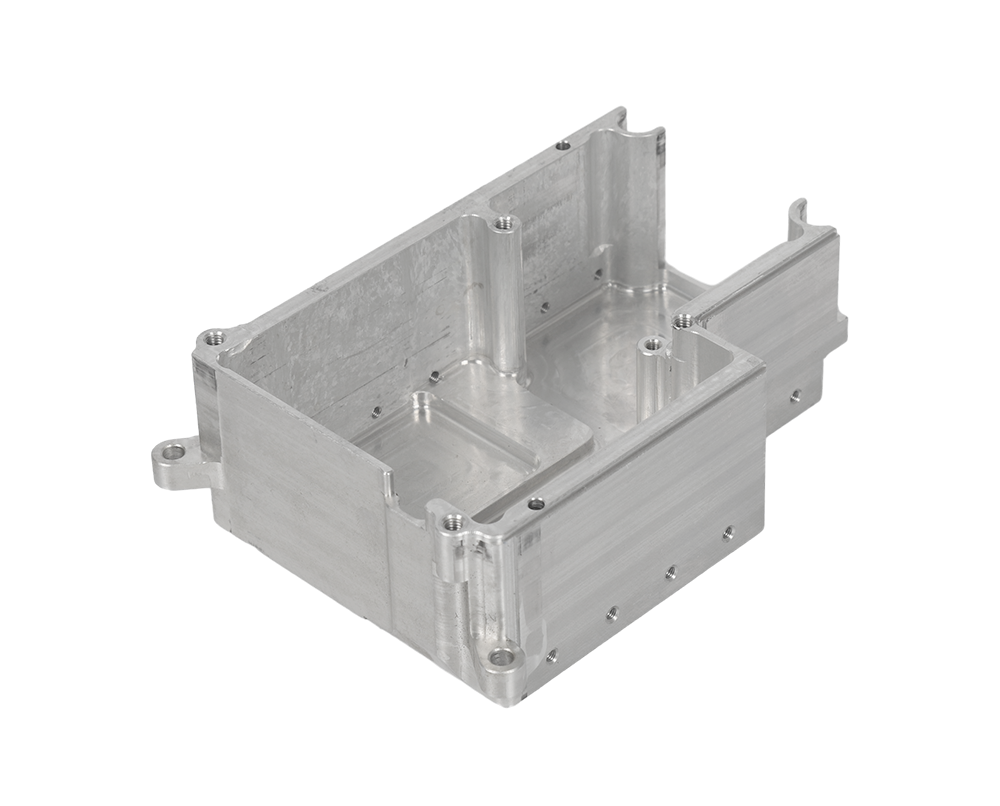

Die casting customization

Therefore, when selecting the tonnage of the die-casting machine, careful consideration must be given to the expected production demand, required casting size and quality requirements, material types, and available budget. Choosing an appropriate tonnage of machine is a key factor in ensuring high-quality die-casting production. In the early stage of project evaluation, engineers will participate in project reviews to provide the most efficient and cost-effective die-casting production plan!

Read recommendations:

custom aluminum extrusion profiles

Why aluminum alloy die castings turn black

pressure die casting components.Customized Zinc Alloy Die Casting - Quality Assurance is Detected

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible