2023-12-12 hits:0 source:News

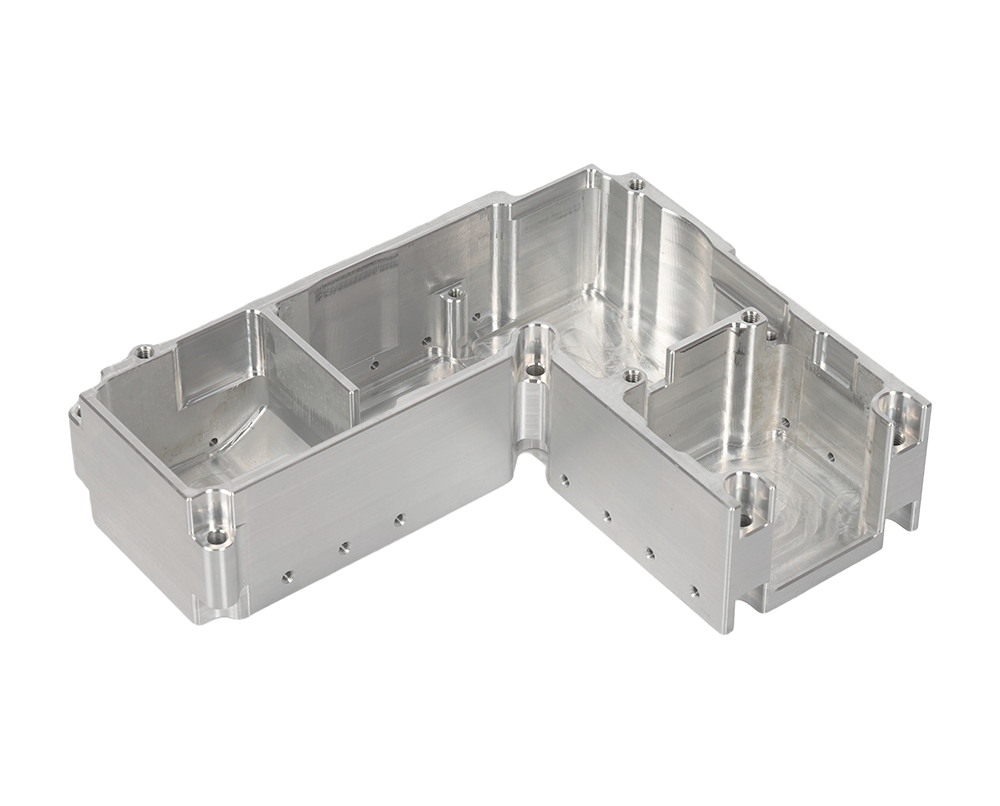

1. Can manufacture metal parts with complex shapes, clear contours, and thin-walled deep cavities. Due to the fluidity maintained by molten metal under high pressure and high speed, it is possible to obtain metal parts that are difficult to process by other process methods.

2. The dimensional accuracy of die-casting parts is high, up to IT11-13 level, sometimes up to IT9 level, with a surface roughness of Ra0.8-3.2um and good interchangeability.

3. High material utilization rate. Due to the high precision of die castings, they can be assembled and used with only a small amount of mechanical processing. Some die castings can be directly assembled and used, with a material utilization rate of 60% -80% and a blank utilization rate of 90%.

4. High production efficiency, due to high-speed filling and short filling time, the metal industry solidifies quickly, and the die-casting operation cycle speed is fast. Among various casting processes, the die-casting method has high productivity and is suitable for large-scale production.

5. Convenient to use inserts, easy to set up positioning mechanisms on die-casting molds, and convenient for embedding inserts.

Read recommendations:

Aluminum automotive die-casting housing manufacturer

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible