2023-12-19 hits:0 source:News

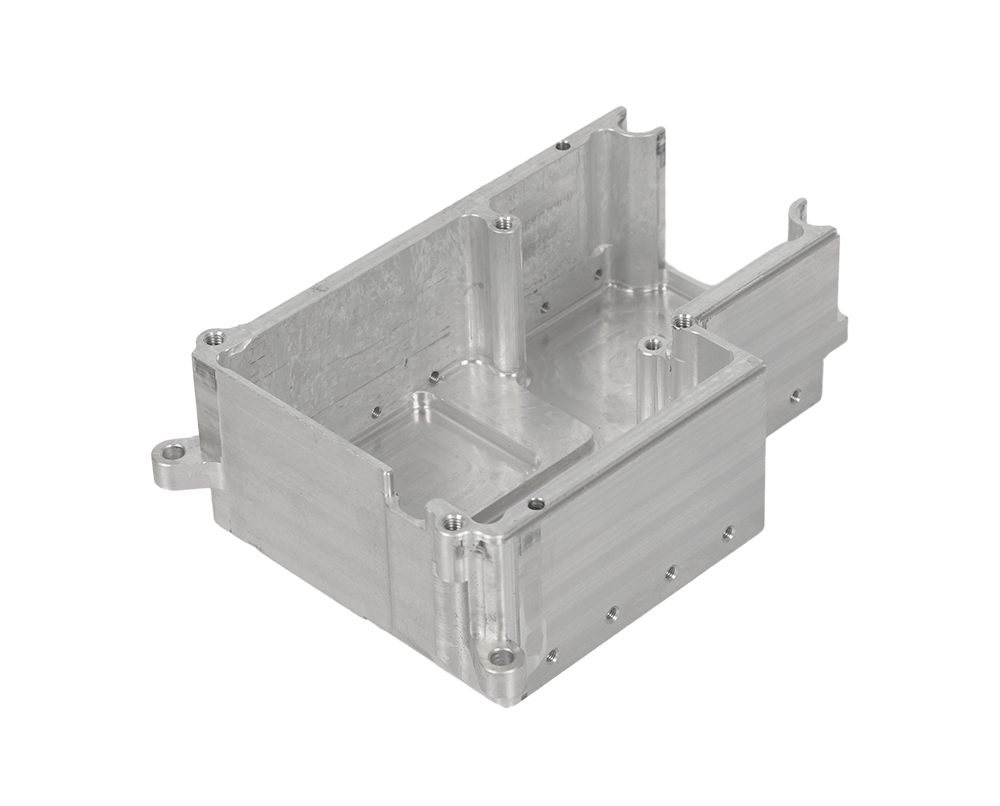

Aluminum alloy die-casting parts will have burrs after production, so burrs will be removed. With the development of technology, although there are advanced deburring equipment, manual deburring is also indispensable. So what are the advantages of manual deburring?

1、 Products with manual deburring are targeted and can remove various types of complex products. They can be selected according to the process, and different things have different targeting.

2、 Manual deburring tools are more environmentally friendly and portable, and can save costs when used. The volume of deburring tools is mostly small and delicate, and they do not produce noise during use.

3、 The flexibility of manual deburring is high, and the deburring method can be flexibly changed according to manual operation.

There are many ways to remove burrs from aluminum alloy die-casting parts, with different advantages and disadvantages. Die-casting has advanced deburring equipment, coupled with manual reprocessing, resulting in smooth, burr free, and pitting free castings. If you have customized requirements for die-casting parts, feel free to contact die-casting for a try!

Read recommendations:

4040 t slot aluminium extrusion

aluminium sliding door profiles

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible