2024-11-05 hits:0 source:News

Die casting and low pressure casting are two distinct manufacturing processes with several differences.

Process Mechanism:

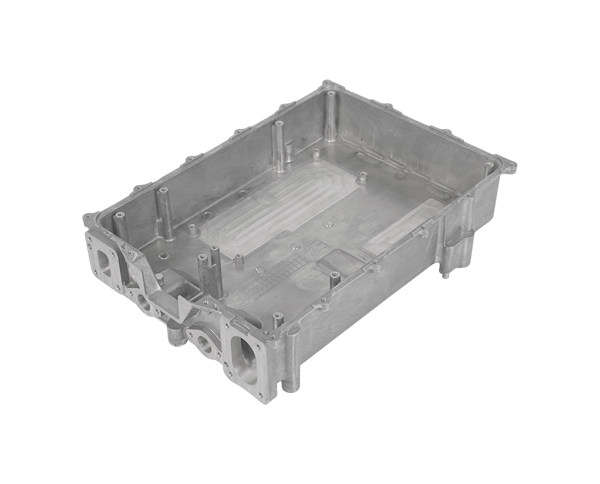

Die casting involves injecting molten metal under high pressure into a steel die. The pressure can range from several thousand to tens of thousands of psi. This rapid and forceful injection allows for the quick filling of the die cavity, resulting in high production rates. For example, in the production of aluminum alloy automotive parts like engine housings, die casting can produce a part in a matter of seconds.

Low pressure casting, on the other hand, uses a relatively low pressure, typically around 0.5 to 10 psi, to force the molten metal into the mold. The metal is drawn up from a crucible into the mold cavity through a pressure differential. This slower and more controlled filling process can lead to better quality in terms of reduced porosity and improved mechanical properties. It is often used for casting complex and high-quality aluminum alloy wheels where a finer microstructure is desired.

Part Quality:

Die cast parts tend to have a thinner wall thickness capability, usually down to around 0.5 mm or even thinner in some cases. However, they may have some internal porosity due to the high-pressure injection. The surface finish of die cast parts is generally good but may require some post-processing for a very smooth finish.

Low pressure cast parts usually have better internal quality with less porosity. They can also achieve a good surface finish, and in many cases, may require less post-processing. The mechanical properties of low pressure cast parts can be more consistent and often better than die cast parts, especially for applications where strength and ductility are important.

Read recommendations:

universal t track aluminum extrusion for woodworking

Aluminum Multiport Adapter Housing

aluminium window frame extrusions

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible