2024-12-11 hits:0 source:News

Die casting is a crucial manufacturing process for fire hydrant fittings. The die casting process offers several advantages in the production of these essential components. It allows for the creation of highly precise and complex shapes with tight tolerances. Fire hydrant fittings need to have accurate dimensions to ensure proper assembly and functionality. Die casting can achieve this level of precision, ensuring that each fitting mates perfectly with other parts of the hydrant system.

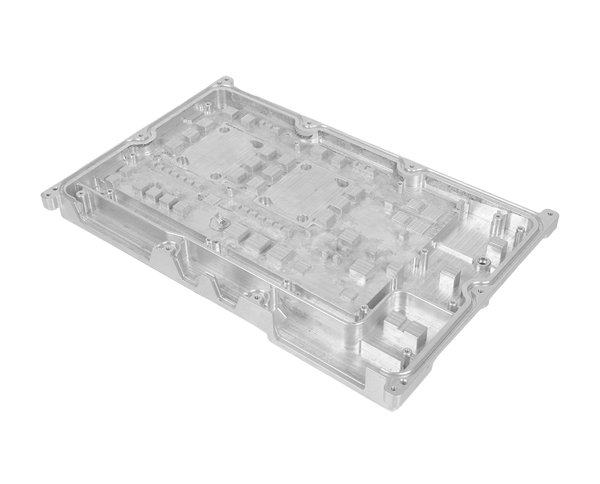

The materials used in die casting for fire hydrant fittings are typically metals with good strength and corrosion resistance properties, such as aluminum alloys or zinc alloys. Aluminum alloys are popular due to their lightweight nature and relatively good strength-to-weight ratio. They can withstand the pressure and environmental conditions that fire hydrants are exposed to. Zinc alloys, on the other hand, offer excellent casting characteristics and good surface finish. The die casting process involves injecting molten metal into a precisely machined mold cavity under high pressure. This rapid filling of the mold ensures that the metal takes the shape of the cavity quickly and uniformly, reducing the likelihood of defects. After solidification, the cast fittings are removed from the mold and may undergo further finishing operations such as machining, polishing, or surface treatment to enhance their appearance and performance. Quality control is of utmost importance in die casting fire hydrant fittings. Each fitting is inspected for dimensional accuracy, surface quality, and integrity to ensure that it meets the strict safety and performance standards required for fire protection systems.

Read recommendations:

standard aluminum extrusion profiles

aluminium profiles builders warehouse