2025-01-03 hits:0 source:News

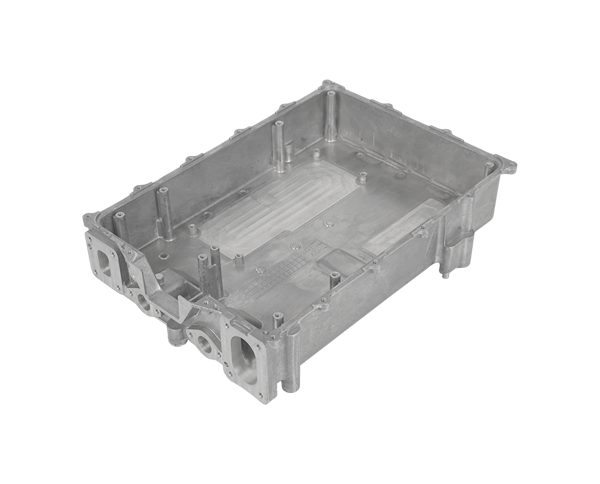

Die casting educational toy accessories are an important part of the toy manufacturing industry. Die casting is a manufacturing process that involves forcing molten metal under high pressure into a mold cavity. This process allows for the production of complex shapes with high precision and repeatability.

Educational toy accessories made through die casting can include parts such as gears, wheels, connectors, and building blocks. These accessories are designed to be durable and safe for children to use, while also providing educational value. For example, gears can be used to teach children about mechanical principles, while building blocks can help develop spatial awareness and creativity.

One of the advantages of die casting for educational toy accessories is the ability to produce large quantities of parts quickly and efficiently. This makes it possible to meet the high demand for educational toys while keeping costs relatively low. Additionally, die casting allows for the use of a wide range of metals, including zinc, aluminum, and magnesium, which can be chosen based on the specific requirements of the toy.

die casting educational toy accessories play an important role in providing children with safe, durable, and educational toys. The die casting process offers several advantages, including high precision, repeatability, and the ability to produce large quantities quickly. As the demand for educational toys continues to grow, die casting will likely remain an important manufacturing method for producing toy accessories.

Read recommendations:

custom aluminium extrusion cost

aluminum extrusion linear rail

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible