2025-01-09 hits:0 source:News

Die casting CNC machining is a manufacturing process that combines the precision of computer numerical control (CNC) machining with the efficiency of die casting. This process is widely used in various industries to produce high-quality, complex metal parts.

Die casting is a manufacturing method where molten metal is injected under high pressure into a mold cavity. The mold is usually made of steel and is designed to produce the desired shape of the part. Once the metal has solidified, the mold is opened and the part is ejected.

CNC machining, on the other hand, is a subtractive manufacturing process where a computer-controlled machine tool removes material from a workpiece to create a specific shape. This process is highly accurate and can produce parts with tight tolerances and complex geometries.

In die casting CNC machining, the die cast part is further processed using CNC machining to achieve the final dimensions and surface finish. This can include operations such as milling, drilling, turning, and grinding. The CNC machine tool is programmed to follow a specific path and remove material in a controlled manner to ensure the part meets the required specifications.

One of the main advantages of die casting CNC machining is the ability to produce complex parts with high precision and repeatability. The die casting process allows for the creation of intricate shapes and thin walls, while the CNC machining ensures accurate dimensions and a smooth surface finish.

Another advantage is the efficiency of the process. Die casting can produce large quantities of parts quickly, and the subsequent CNC machining can be performed relatively quickly as well. This makes it a cost-effective option for high-volume production.

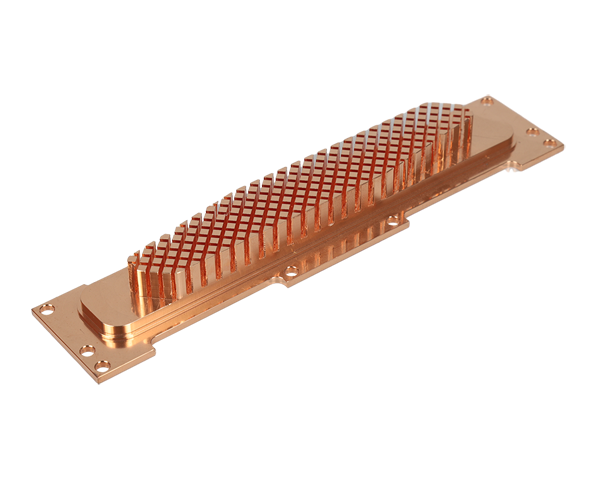

Furthermore, die casting CNC machining can be used to produce parts in a wide range of materials, including aluminum, zinc, magnesium, and copper alloys. This allows for flexibility in material selection based on the specific requirements of the application.

In conclusion, die casting CNC machining is a powerful manufacturing process that combines the advantages of die casting and CNC machining. It offers high precision, complex geometries, and efficient production, making it a popular choice for many industries.

Read recommendations:

aluminum electronic enclosures boxes

Applications of Aluminum Die - Castings

Which factory can do die-cast aluminum oxidation treatment.aluminum sheet fabrication