2024-11-22 hits:0 source:News

Die - casting of lamp fittings is a specialized area within the manufacturing domain, with several important considerations.

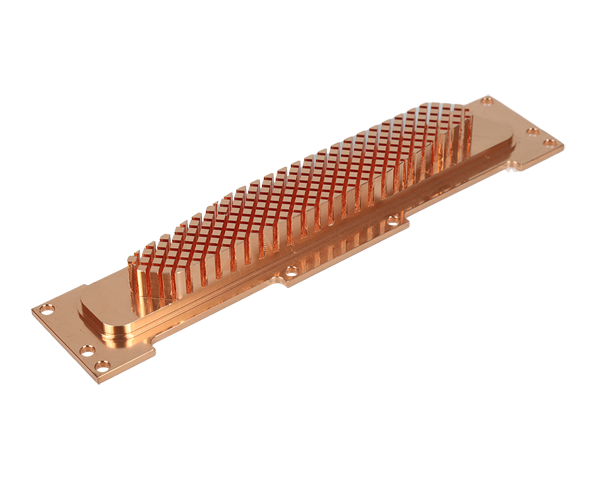

When it comes to material selection for die - casting lamp fittings, different alloys are used based on the specific requirements of the lamp. For example, if the lamp fitting needs to have good heat dissipation properties, aluminum - based alloys are often preferred. Aluminum has excellent thermal conductivity, which helps in dissipating the heat generated by the light source. On the other hand, if the fitting requires a more decorative look with a certain level of strength, zinc - based alloys with their ability to hold fine details during casting can be a good choice.

The die - casting die for lamp fittings must be designed with great precision. Lamp fittings often have complex geometries, including threaded parts for attaching bulbs or shades, and decorative elements. The die needs to accurately reproduce these features. The gating system in the die is designed to ensure that the molten alloy can reach all the necessary areas of the cavity without causing any defects. For example, in fittings with intricate patterns, the gating should be such that the alloy flow does not disrupt the formation of these patterns.

During the die - casting process, the control of parameters is crucial. The injection temperature of the molten alloy is carefully set to ensure its proper flow within the die cavity. The injection pressure and time are adjusted to fill the die completely, taking into account the complexity of the fitting's shape. The cooling process is also carefully managed to prevent warping or cracking of the lamp fitting. After die - casting, additional operations may be required. This can include machining to achieve the required tolerances for threaded parts, surface finishing to give a smooth and attractive appearance, and sometimes electroplating to improve corrosion resistance and aesthetics. Quality control throughout the process ensures that the die - cast lamp fittings meet the standards for both functionality and visual appeal in lighting applications.

Read recommendations:

Industrial Aluminum Profile Extrusion company

aluminum extrusion distributors

aluminum heatsink extrusion profiles

What are the advantages of anodizing aluminum alloy die castings?

aluminum sign frame extrusions.Introduction to the Mold of Zinc Alloy Die Casting Process

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible