2024-10-14 hits:0 source:News

Die - casting has become a crucial manufacturing method in the production of model toy die - casting. This process offers several distinct advantages for creating high - quality model toys.

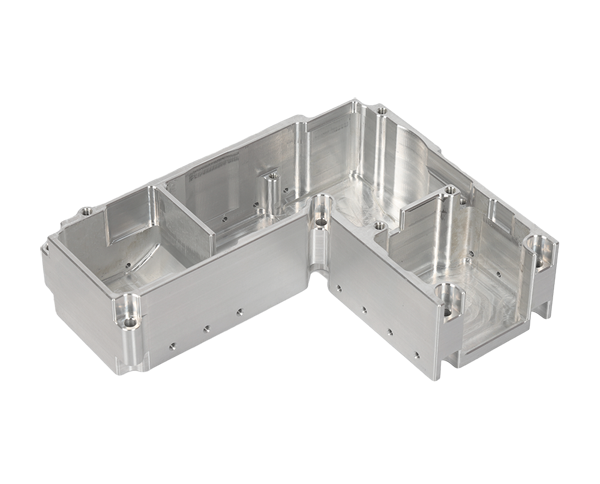

Firstly, die - casting enables the production of highly detailed and complex shapes. Model toys often require intricate designs, such as miniature replicas of vehicles, aircraft, or fictional characters. Die - casting can accurately reproduce fine details like engine parts in a model car or the delicate features of a character's face. The molds used in die - casting can be precisely engineered to capture every nuance of the original design.

Secondly, die - casting provides excellent dimensional accuracy. This is vital for model toys as it ensures that all the parts fit together precisely. For example, in a model kit of a building, the walls and floors need to be of the exact dimensions to assemble correctly. The high - pressure die - casting process forces the molten metal into the mold cavities, resulting in parts with tight tolerances.

In terms of material selection, die - casting allows for a variety of metals and alloys. For model toys, zinc - based alloys are commonly used. These alloys offer a good balance between strength and cost. They are also relatively easy to work with in the die - casting process and can be painted or finished easily to give the model a realistic look.

Moreover, die - casting is a relatively fast production method. Once the mold is set up, multiple parts can be produced in a short amount of time. This is beneficial for mass - producing model toys to meet market demands. However, die - casting also has some challenges in the context of model toys. The initial cost of creating the molds can be high, especially for small - scale production runs. But as the production volume increases, the cost per unit decreases, making it a cost - effective option for larger - scale model toy manufacturing.

Read recommendations:

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible