2024-11-19 hits:0 source:News

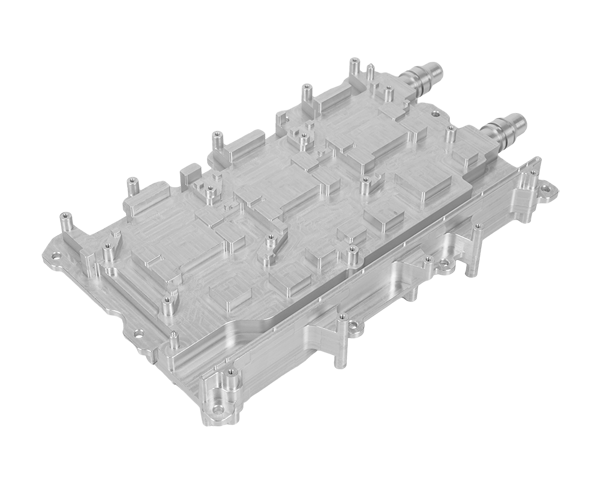

Die - casting of lens accessories is a highly specialized manufacturing process with several crucial aspects. Firstly, the material selection for die - casting lens accessories is of utmost importance. High - quality alloys are typically used, such as aluminum - based or zinc - based alloys. These alloys possess excellent fluidity during the die - casting process, ensuring that they can fill the intricate molds precisely.

The molds used in this process are designed with high precision. They are often made from hardened steel to withstand the high pressures involved in die - casting. The design of the mold cavities takes into account the exact shape and dimensions of the lens accessories. For example, the curvature and thickness of the lens mount need to be accurately replicated to ensure proper fit and function.

During the die - casting operation, temperature control is vital. The molten alloy needs to be maintained at an optimal temperature range. If the temperature is too low, the alloy may not flow smoothly, leading to incomplete casting. On the other hand, if it is too high, it can cause defects like porosity in the final product.

Quality control measures are extensive in die - casting lens accessories. Visual inspection is carried out to check for any surface defects such as cracks, burrs, or rough edges. Dimensional measurements are also made using precision measuring tools to ensure that the accessories meet the required tolerances. Additionally, mechanical testing may be performed to assess the strength and durability of the cast parts, as they need to be able to withstand the mechanical stresses during the assembly and use of the lens.

Moreover, post - die - casting processes are often involved. This may include machining operations to achieve even more precise dimensions, as well as surface finishing treatments like polishing to improve the optical properties of the lens accessories. The die - casting process for lens accessories requires a combination of advanced technology, skilled operators, and strict quality control to produce high - quality components that are essential for the performance of the lens.

Read recommendations:

aluminum extrusions for screen enclosures

Thermal Conductivity Performance Parameters of Aluminum Profiles

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible