2023-10-10 hits:0 source:News

In many industries, companies often resort to paint instead of color anodized products due to the prevalent issue of color variation and lower costs. This practice poses two significant problems. First, painted surfaces are prone to chipping and peeling, rendering them less durable compared to anodized finishes. Second, paint has detrimental effects on the environment, as it complicates the recycling process and introduces harmful substances. In other occasions, manufacturers shy away from colored anodizing and settle on clear anodizing to avoid complications in the coloring step due to the misconception that colored anodizing is more challenging than clear anodizing.

This article aims to dispel this notion and demonstrate that achieving consistent color in anodizing is not more challenging than clear anodizing and that anodizing creates a much better surface finish than paint. This article will guide readers on avoiding common mistakes when opting for colored anodized aluminum products, enabling manufacturers to communicate specifications to anodizers that will ensure a uniform coloring for all products.

The Challenge of Color Variation in Anodizing

Color variation in anodizing can be better understood by exploring the anodizing and coloring processes, which have been explained in more depth in a previous article.1 Anodizing is a process that involves the creation of a porous oxide layer integrated with the surface of aluminum. This layer serves two important purposes: it enhances the aluminum’s resistance to corrosion and provides a base for applying colors in the coloring step. Unlike traditional painting methods, anodizing integrates the colored coating into the aluminum material itself. The porous structure of the oxide layer serves as a sponge, collecting the color in microscopic pockets that are then sealed in the next step of the anodizing process. This integration enhances the durability of the colors and reduces the chances of chipping or peeling. As a result, anodized aluminum parts exhibit greater resilience and can withstand wear and tear more effectively than their painted counterparts.

However, there are three caveats to consider when it comes to color anodizing. First, while paints offer a vast array of colors and shades, the color options for anodized aluminum are more limited. Second, the color anodized layer is transparent, thus showing the surface of the aluminum underneath. Third, it is crucial to take into account the environmental conditions that the products will be exposed to in order to select the appropriate anodic coloring process.

It might be tempting to consider clear anodization without color to gain the aesthetic appearance while avoiding potential complications. However, coloring anodized aluminum is not inherently more challenging than clear anodization. Both processes involve similar considerations and potential difficulties. Most color variations that happen before the aluminum product is used in its final environment are due to variations in the clear oxide layer. In other words, the color variations happen with or without the coloring step.

Minimizing Color Variation in Anodizing

When considering anodizing, whether for clear or color finishes, it is important to understand that variations in color outcomes are not arbitrary but stem from specific factors. Following are the key factors that contribute to variations in the clear or color anodized surface.

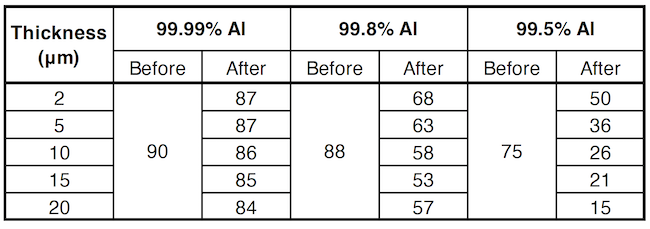

Variations in the Thickness of Oxide Layer: Even within the same anodizing process, variations in the thickness of the oxide layer can occur. These variations affect the reflection of light through the layer, which can result in color differences across the surface of the part. Table I shows how the reflectiveness of the coating changes depending on the thickness and alloying elements.

Table I. Reflectivity based on thickness and alloying elements.

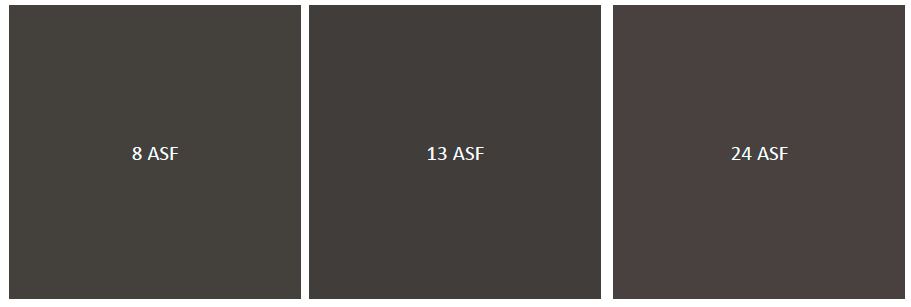

Variations in the Structure of the Oxide Layer: The structure of the oxide layer formed during the anodizing process (which occurs when the current converts the aluminum into aluminum oxide) can vary a lot depending on the process parameters, such as current density, temperature, and concentration (Figure 1). Here, the variation in current density shows how the black colored oxide layer will appear more or less brownish depending on the current density.

Figure 1. Three different current densities showing different color appearance results.2

Variations in Alloying Elements: The presence of alloying elements in aluminum affects the final color of anodized parts. Choosing alloys with minimal alloying elements or specifying allowable ranges can help address anticipated color variations.

Variations in Pretreatment: The transparency of the oxide layer formed during anodizing allows for the underlying material to be visible, revealing any variations caused by different pretreatments or etching methods. These differences will be seen as color variation (Figure 2).

Figure 2. Color variations due to different mechanical pretreatments.

Variations in the Coloring Process: Precise control of parameters such as temperature, immersion time, and concentration of coloring agents is essential for consistent and desired color development. Regular monitoring and adjustment of these parameters help maintain color consistency over time.

Variations in the Sealing Process: Selecting appropriate sealing methods that enhance corrosion resistance and color stability is crucial. Optimal pH levels during sealing and avoiding values below pH 5 prevent long-term color deterioration. Note that some of the sealing methods show more greenish or yellowish color after sealing.

Variations in Quality Control: Many customers still rely on visual samples to communicate their desired color finish. But as the perception of color can vary from person to person this is a less reliable method. By using numerical values, such as the Commission Internationale de l’Éclairage (CIE) method, precise color specifications can be communicated, eliminating ambiguity and reducing the potential for variations.

Effective Communication with Anodizers: Effective communication with anodizers is vital for minimizing color variations and achieving the desired outcomes in anodized products. By engaging in open and detailed communication with the anodizer, the aluminum manufacturer or OEM can gain insights into the factors influencing color outcomes, work collaboratively to address color variations, and achieve consistent and desired coloring in anodized products. When considering the anodizing process, the following topics can help facilitate meaningful discussions with the anodizer:

· Alloying Elements – What are the alloying elements in the aluminum alloy chosen, and how much can they vary within composition from batch to batch? How do these elements affect the final color of anodized parts? Talking with the anodizer and understanding the impact of alloying elements on the anodizing process helps address color variations and select appropriate alloys.

· Consistency in the Structure of the Oxide Layer – Running the current density so that it is controlled according to a fixed thickness while recording temperature, process time, and voltage during the process is a good starting point to make sure structure of the oxide layer is consistent.

· Process Parameters in the Coloring Tank – Make samples and measure the color to get its ∆E values, so the anodizer knows what key parameters to test in the coloring tank—such as temperature, immersion time, and concentration of coloring agents.

· Sealing Process – What sealing method is used, and how does it affect the final appearance? The choice of sealing method can influence color stability and corrosion resistance.

The previous sections have mostly been about including a coloring step into the anodizing process. However, color variations also happen on clear anodized aluminum parts. One of the most well-known examples in Denmark is the top of the Opera House in Copenhagen (Figure 3), where the variation in thickness, structure of the rolled plate, and small variation in alloying element led to a patchy covered tower.

Figure 3. The Copenhagen Opera House in Denmark. (Photo: Nathan Siemers.)

Case Study

A client of AluConsult faced an issue with a yellowish hue appearing on the aluminum panels used for a building façade. The main discussion centered around determining whether the problem was related to the aluminum material itself or a fault in the anodizing process.

One potential cause could have been thicker coatings, especially in alloys containing chromium (Cr), which may result in a yellowish appearance. Upon further examination of the aluminum material, it was identified as 6063 aluminum, ruling out the alloy as the source of the issue.

Next, the sealing process was examined as the possible root cause of the yellowish hue. A description of the sealing solutions from the anodizing company was obtained, and a test was conducted on 6063 aluminum plates using four different sealing solutions.

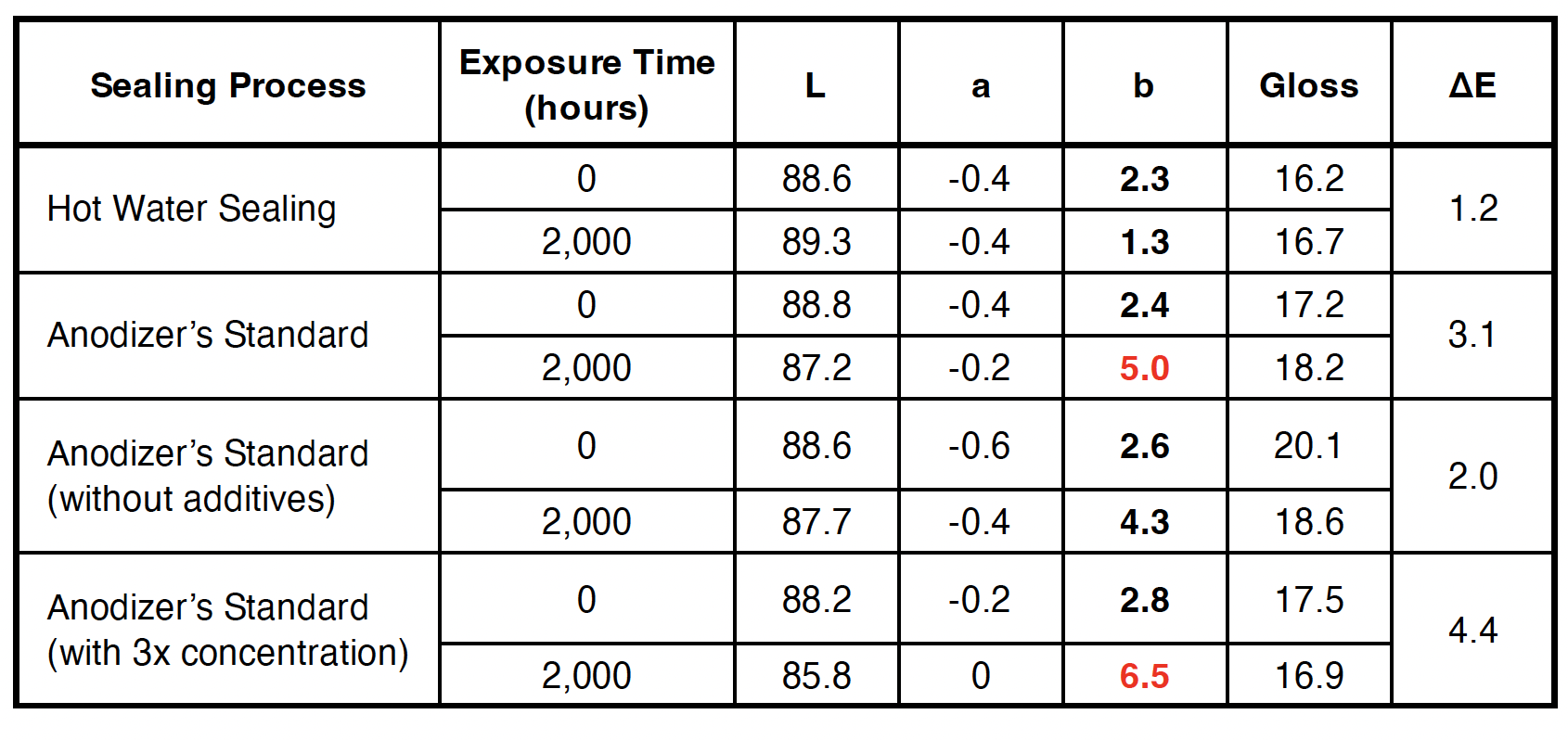

For the test, the sealing process was performed with three different concentrations, along with hot water sealing, to compare the results. The sealed aluminum plates were then subjected to 2,000 hours of UVB light exposure following the ASTM G 154-06 standard. Color measurements were taken both before and after the ultraviolet B (UVB) exposure.

The impact of the UVB radiation exposure on the samples was assessed by measuring the change in color and gloss using the CIE system, which defines axes corresponding to the three primary colors (L = lightness value, a = green/magenta, and b = blue/yellow). The total color difference, represented as ∆E*, was calculated, representing the difference between the L*, a*, and b* values of the sample and standard. Table II displays the ∆E values for the four different sealing solutions, representing the color difference between the anodized surface before (0 hours) and after the UVB test (2,000 hours).

Table II. Results of the color and gloss measurements for all four types of sealing solutions.

The results indicated that the sealing process utilized by the anodizer was responsible for the yellowing issue. Before exposure, all sealings had nearly the same b-value (ranging from 2.3 to 2.8). However, after 2,000 hours of exposure, the b-value almost doubled for the anodizer’s solution, resulting in a more pronounced yellowish hue, which was also evident upon visual inspection (Figure 4).

Figure 4. Visual impression of the different sealing solutions (L-R): hot water sealing, anodizer’s standard, anodizer’s standard without additives, and three times concentration.

Moreover, by tripling the concentration of the additive, this yellowish hue became even more prominent. Notably, the table demonstrated that even without any additive mixed into the sealing tank, there was still yellowing of the surface, leading to the conclusion that the sealing product used in the process was the cause of the damage.

This case study shows not only a methodical approach to identifying the root cause of color variations in anodized aluminum, but also highlights the possibility of variations in clear anodizing.

Conclusion

It is important to recognize that color variations can occur in both clear and colored anodizing processes. However, understanding the factors influencing these variations and implementing effective strategies can lead to consistent and desired coloring in anodized aluminum products. By adhering to process parameters, considering alloying elements, optimizing sealing methods, and maintaining open communication with anodizers, manufacturers can achieve stunning and durable finishes that surpass the limitations of paint and overcome the challenges of clear and colored anodizing.

Read recommendations:

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible