2025-02-27 hits:0 source:News

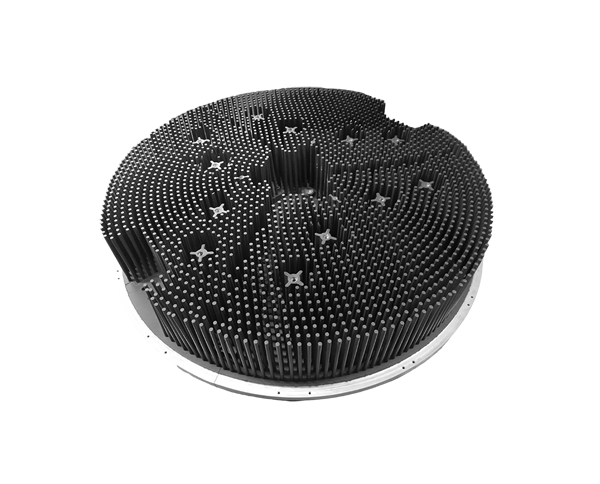

Aluminum die - castings have gained significant popularity in various industries, and one of the key questions regarding them is their durability. In general, aluminum die - castings exhibit remarkable durability, making them a preferred choice for many applications.

Firstly, aluminum has a relatively high strength - to - weight ratio. When formed into die - cast components, it can withstand substantial mechanical stresses. For example, in automotive applications, aluminum die - cast engine blocks are required to endure the high - pressure combustion forces within the cylinders. These engine blocks are designed to last for hundreds of thousands of kilometers under extreme operating conditions. The die - casting process allows for the creation of complex shapes with uniform wall thicknesses, which helps in evenly distributing the applied forces and enhancing the overall structural integrity.

Secondly, aluminum has good corrosion resistance. It forms a thin, self - protecting oxide layer on its surface when exposed to air. This oxide layer acts as a barrier, preventing further oxidation and corrosion. In outdoor applications such as street lamps and building facades, aluminum die - cast parts can maintain their integrity for long periods without significant degradation. Even in harsh environments with high humidity or exposure to chemicals, the corrosion - resistant properties of aluminum die - castings ensure their long - term durability.

Moreover, the durability of aluminum die - castings can be further enhanced through post - processing treatments. Heat treatment, for instance, can improve the mechanical properties of the castings. By carefully controlling the heating and cooling processes, the internal structure of the aluminum can be optimized, increasing its hardness, strength, and fatigue resistance. Surface treatments like anodizing can also be applied to add an extra layer of protection, making the castings more resistant to wear and environmental factors.

However, the durability of aluminum die - castings also depends on proper design and manufacturing processes. Defects such as porosity, improper alloy composition, or incorrect heat treatment can significantly reduce the lifespan of the castings. Therefore, quality control during production is crucial to ensure the high - level durability expected from aluminum die - cast components.

Read recommendations:

aluminum profile machining center

aluminum extrusion linear rail

Zinc alloy die-casting process to find the correct positioning has a future

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible