2024-10-22 hits:0 source:News

Die cast magnesium alloy offers several significant advantages1. LightweightMagnesium is one of the lightest structural metals available. Die cast magnesium alloy products are extremely lightweight compared to many other materials such as steel and aluminum. This makes them ideal for applications where weight reduction is crucial, such as in the automotive and aerospace industries. For example, in automobiles, using die cast magnesium alloy parts can help improve fuel efficiency by reducing the overall weight of the vehicle.

2. High Strength-to-Weight RatioDespite being lightweight, die cast magnesium alloy has a high strength-to-weight ratio. This means that it can withstand significant mechanical stress while still maintaining its lightweight nature. It is capable of withstanding impacts and vibrations, making it suitable for use in demanding applications. For instance, in electronic devices, magnesium alloy casings can provide protection to the internal components while keeping the overall weight of the device low.

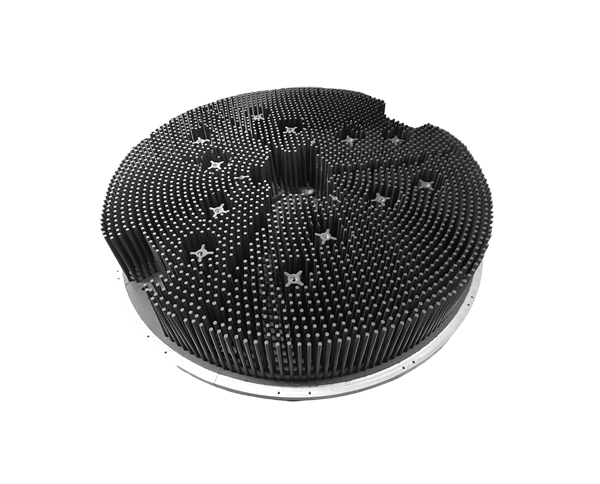

3. Excellent Thermal ConductivityMagnesium alloy has good thermal conductivity, which allows it to dissipate heat quickly. This property is beneficial in applications where heat management is important, such as in electronic components and power tools. The ability to conduct heat away from sensitive parts helps to prevent overheating and prolong the lifespan of the product.

4. Good Die CastabilityMagnesium alloy is highly suitable for die casting processes. It flows easily into complex molds, enabling the production of intricate and detailed parts. This allows for the creation of designs that may be difficult or impossible to achieve with other materials. Moreover, die casting can produce parts with a high degree of accuracy and surface finish, reducing the need for additional machining and finishing operations.

5. RecyclabilityMagnesium alloy is highly recyclable. At the end of a product's life cycle, the magnesium alloy parts can be melted down and reused to make new products. This not only reduces waste but also conserves resources and energy.

Read recommendations:

2020 series aluminum extrusion

aluminium profile price per kg

How to choose a high-quality aluminum alloy die-casting factory for cooperation

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible