2024-01-11 hits:0 source:News

The application of aluminum alloy die castings is widespread in various industries, with a huge market demand. However, during the production process, the problem of mucosal strain on aluminum alloy die castings is easy to occur. Today, the editor will explain the causes and solutions for this problem.

Adhesive mold damage is a scratch mark caused by the adhesion between the die cast alloy and the mold wall, which can be torn in severe areas. The reasons for adhesive mold strain are as follows

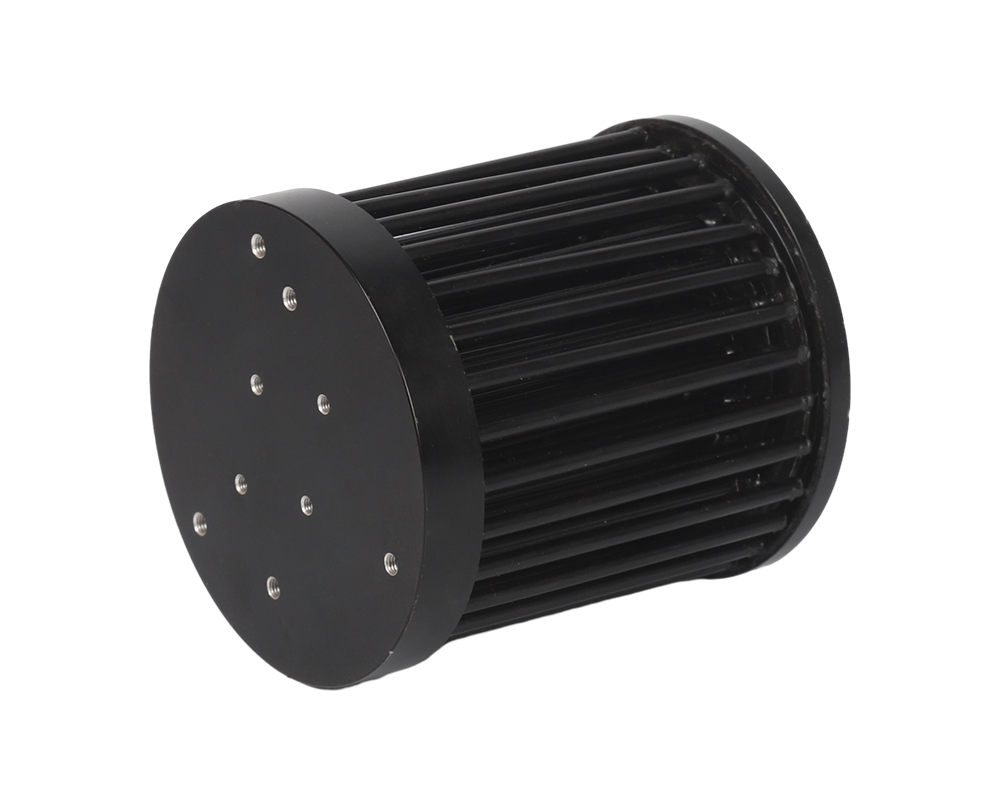

Radiator housing 1

① High alloy pouring temperature

② Model temperature too high

③ Insufficient or incorrect use of paint

④ The surface of certain parts of the model is rough

⑤ Incorrect pouring system, causing the alloy to impact the mold wall or core from the front side

⑥ Improper use of model materials or incorrect heat treatment process, insufficient hardness

⑦ Filling speed too high

⑧ Aluminum alloy has too little Fe content (Wr.<0.6%)

Solution:

① Reduce pouring temperature

② Model temperature control within the process range

③ Eliminating roughness on the surface of the cavity

④ Check if the variety or dosage of paint is appropriate

⑤ Adjust the inner gate to prevent direct impact of molten metal

⑥ Verify the alloy composition to make it suitable

⑦ Check if the model material, heat treatment process, and hardness are reasonable

Read recommendations:

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible