2024-01-16 hits:0 source:News

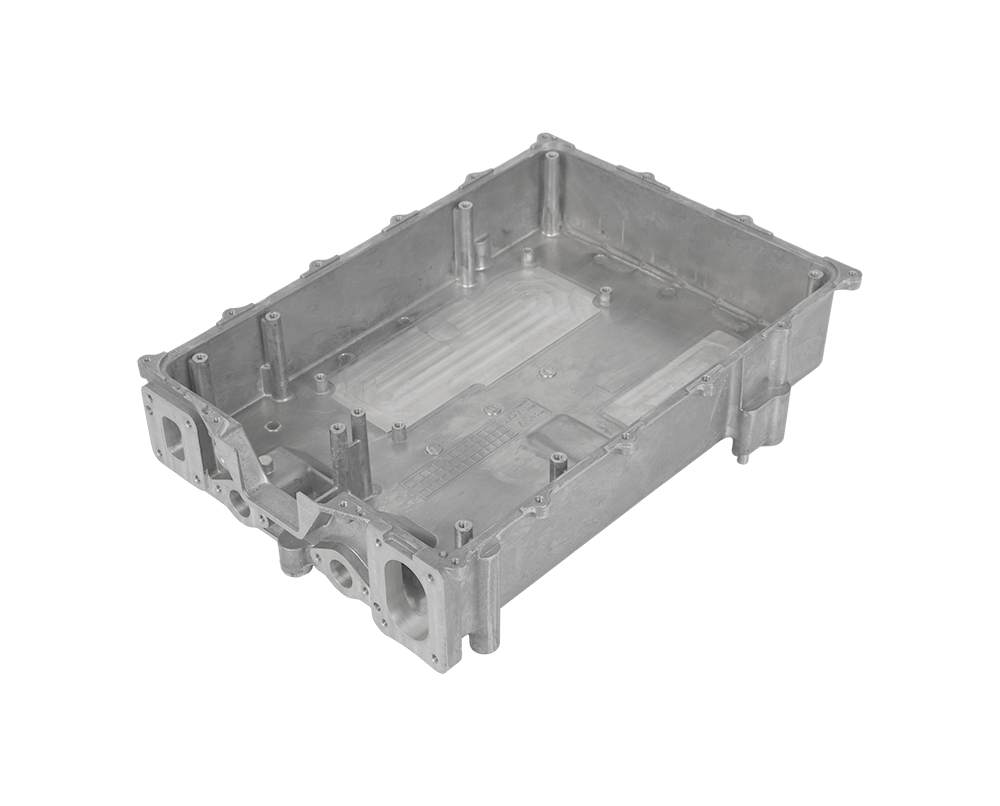

At present, aluminum alloy is the most widely used alloy, and aluminum alloy die castings have been widely used in industry. With the improvement of die casting technology, there are high standards and requirements for the quality of aluminum alloy formed die castings, and the casting surface must not have defects. The appearance of cracks is straight or irregular curves. The surface of hot crack fracture is strongly oxidized to a dark gray or black color, without metallic luster. The surface of cold crack fracture is clean and has metallic luster. Reasons for crack formation:

1. Metal mold casting is prone to crack defects because the metal mold itself does not have yielding properties.

2. Fast cooling speed can easily cause an increase in internal stress in the casting, premature or late opening of the mold, too small or too large pouring angle, and too thin coating layer, all of which can easily cause cracking of the casting. When there are cracks in the mold cavity itself, it is also easy to cause cracks.

Prevention and control methods for cracks:

1. Attention should be paid to the processability of the casting structure, so that areas with uneven wall thickness of the casting can transition uniformly, and appropriate fillet sizes should be used.

2. Adjust the coating thickness to achieve the required cooling rate for each part of the casting as much as possible, avoiding the formation of excessive internal stress.

3. Attention should be paid to the working temperature of the metal mold, adjusting the mold slope, and timely pulling out the core to crack, and taking out the casting for slow cooling.

In summary, if you want to make aluminum alloy die castings defect free and of good quality, finding the right die casting method is right! We do not overlook every detail and strive to satisfy you with every aluminum alloy die-casting product!

Read recommendations:

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible