2024-01-10 hits:0 source:News

Advantages:

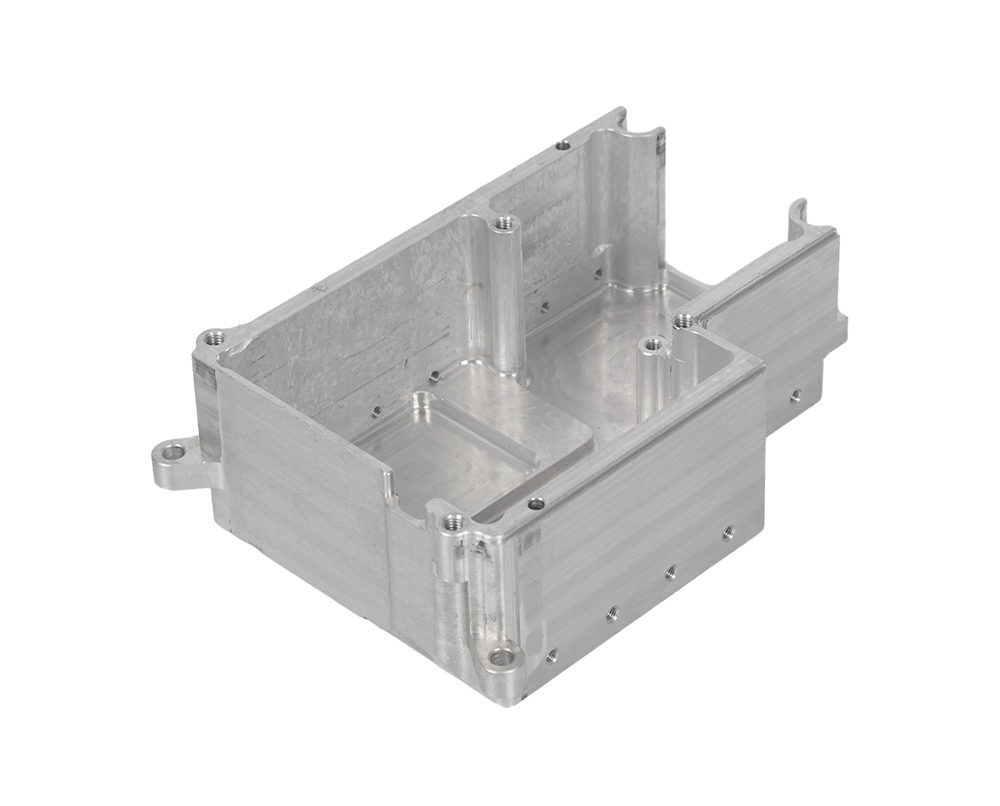

1. Good product quality: The dimensional accuracy of castings is high, generally equivalent to levels 6-7, and even up to level 4; Good surface smoothness, generally equivalent to grades 5-8; The strength and hardness are relatively high, and the strength is generally increased by 25-30% compared to sand casting, but the elongation is reduced by about 70%; Stable size and good interchangeability; Die cast aluminum thin-walled complex castings.

2. High production efficiency: The machine productivity is high, for example, the domestically produced J-III3 horizontal cold air die casting aluminum machine can die cast aluminum 600-700 times on average in eight hours, and the small hot chamber die casting aluminum machine can die cast aluminum 3000-7000 times on average every eight hours; Die cast aluminum molds have a long service life. A pair of die cast aluminum molds and die cast aluminum bell alloys can have a service life of several hundred thousand times, or even millions of times; Easy to achieve mechanization and automation.

3. Excellent economic effect: Due to the precise size and smooth surface of die cast aluminum parts. Generally, it is used directly without mechanical processing, or the processing volume is very small, which not only improves the metal utilization rate but also reduces a large number of processing equipment and working hours; The cost of castings is cheap; Combination die cast aluminum can be used with other metallic or non-metallic materials. It saves both assembly time and metal.

Disadvantages:

1. Due to the high filling speed and unstable flow state of liquid metal in the mold cavity during die casting of aluminum, the general die casting aluminum method is adopted. However, the casting is prone to gas pores and cannot undergo heat treatment.

2. For castings with complex concave surfaces, die-casting aluminum is more difficult.

3. High melting point alloys (such as copper and black metals) have a lower lifespan in die cast aluminum molds.

4. Small batch production is not suitable, mainly due to the high manufacturing cost of die-casting aluminum molds, high production efficiency of die-casting aluminum machines, and uneconomical small batch production.

Read recommendations:

lf you have any questions or comments, you can leave us a message and we will reply to you as soon as possible